Soy Milk

Soy milk is an alternative for cow’s milk, made of ground soybeans mixed with water The milk is very nutritive. It is rich in proteins and isoflavones, low in fat and cholesterol-free. Isoflavones, certain organic chemicals, are in several ways beneficial to one’s health. Soy milk doesn’t contain lactose, which makes it safe for people with lactose intolerance. Because soy milk contains less calcium than cow’s milk, it is often fortified with calcium. Fortification with vitamin D and some vitamin B is also commonly done. By using appropriate processing techniques the beany taste of soy milk can be reduced or eliminated. Nevertheless often flavourings, sugar and salt are added to make the milk more attractive for consumers. In many recipes soy milk can be used as substitute for milk.

Production soy milk

In general, for the production of soy milk soybeans are used with less taste, which are slightly creamy, so the beany taste is avoided and a better texture is obtained. Large soy beans with clear hilum are preferred. The producers often work directly with farmers, so a soybean that produces the best soy milk is grown.

Cleaning

First the soybeans are cleaned. Undesirable parts are removed using a destoner, gravity and sieves. After that the soybeans are polished and sorted by colour.

Dehulling

The cleaned soybeans are steamed and mechanically split in half. By this the bean looses its hull. These hulls are sucked off and processed in animal feed. In this way only the cotyledons are left, which contain all the nutritient elements for the soy milk. An additional benefit of this process is the change in lecithin composition of the soybean, through which the emulsion stability of the soy milk increases.

Blanching

Next the soybeans are blanched in water of 85 to 90°C during 15 to 20 minutes. Because of this the soybean becomes digestible and lipoxygenase is inactivated. In this way oxidation of the present polyunsaturated fatty acids is prevented. By absorbing water the bean swells, becomes softer and therefore better processable.

Grinding

The hydrated soybeans are grinded with soft and cleared water in two steps. The weight proportion between water and beans has to be around 10:1. This ends in a white slurry with minuscule particles. Due to the grinding all the valuable nutrients are released into the water, which leads to a milky oil-in-water emulsion. By homogenisation the release of nutrients is increased, because of the extension of the product surface.

Filtering

The insoluble particles of the soybean are removed with a decanter. These insoluble parts are pressed against the surface by centrifugal acceleration and are carried out of the decanter with an internal screw. The thick soy pulp of fibers that is removed is called okara and has to contain as less water as possible. After addition of water it is possible to pass the removed okara through a second decanter. The so produced wash-water can be returned and used for grinding the soybeans with water. In this way the yield might increase with approximately 10%. The protein content increase even from 4 to 5% in weight. After drying, okara is mainly used in animal feed.

Mixening

In a large tank the other ingredients are added to the soy milk and the total is mixed well.

Sterilizing

It is possible to extend the shelf life of soy milk by pasteurization or sterilization. After pasteurization, combined with cold storage, soy milk can be stored during 8 weeks. But often UHT-sterilization is applied. The soy milk is heated by using steam injection during 5 seconds at 145°C, after which flash cooling occurs. This flash cooling at the same time removes off-flavours.

Homogenizing

To prevent creaming of fat particles, the hot soy milk is homogenized after sterilization.

Cooling

Using a plate heat exchanger the hot, homogenized milk is cooled down to room temperature.

Packaging

Soy milk is often packed through aseptic filling. The cooled soy milk is transported to the packaging machine, where it is wrapped in a cardboard packaging and immediately sealed. From here the packs are automatically packed in boxes and placed on a pallet.

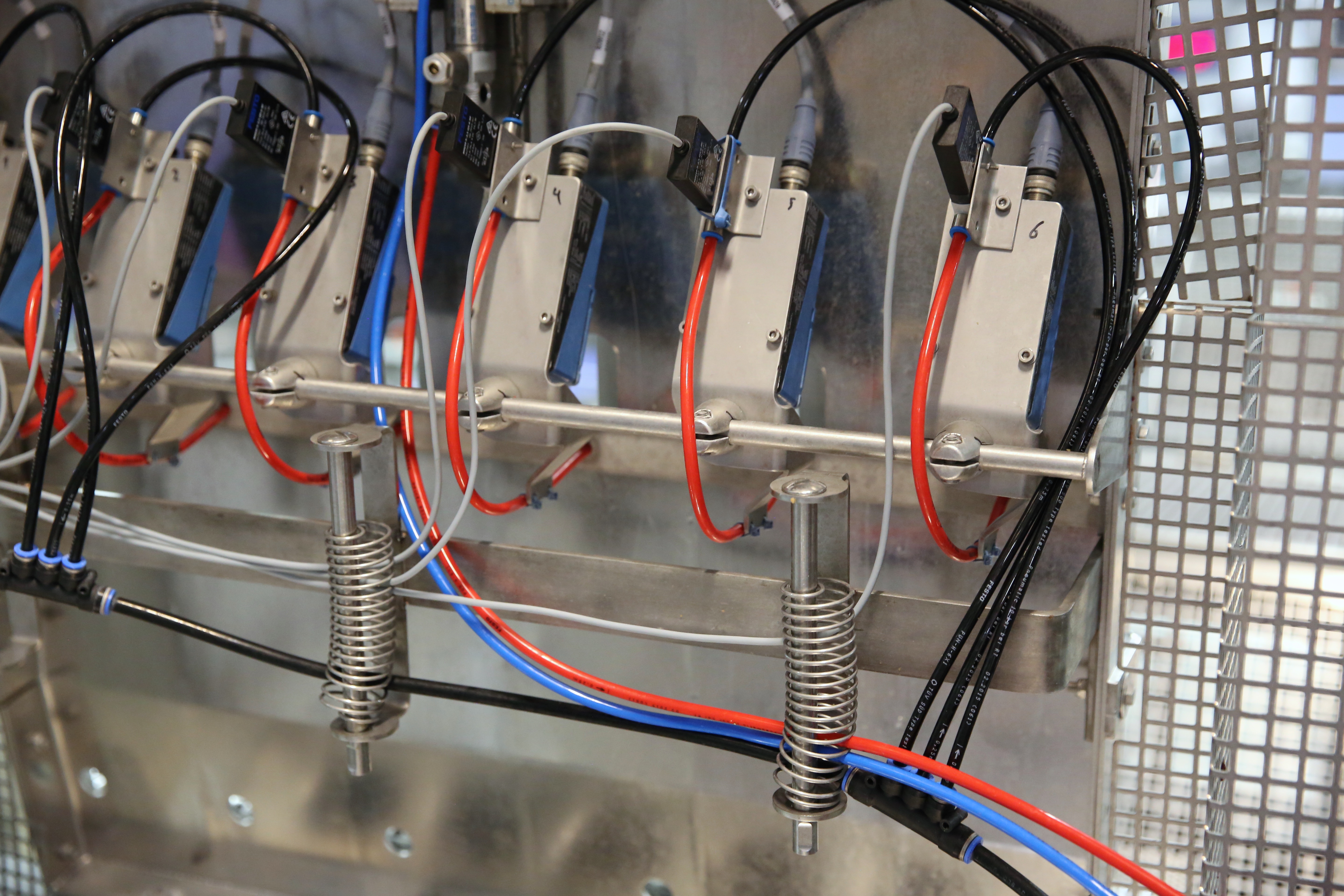

Hygienic cabling at a Unilever factory

The Streamline HD cable support system was explained at a knowledge event. After internal consultation, Ben & Jerry's decided to get started with it. The initial findings are so positive that they are going to prescribe their suppliers to use this form of cabling from now on.

“My boys were quite envious when they heard where I was going”, Michael Evers—Business Development Manager at Niedax Group and Secretary of the national working group Hygienic Cabling— told us, while standing in the reception hall of Ben & Jerry’s factory in Hellendoorn.

It all started in the 1950s; in addition to bread and pastries, Hellendoorn baker Gerrit Valk, decided to start producing ice cream. In the 70s, the production site was moved from the centre of Hellendoorn to its current location in Hellendoorn, and was increasingly automated. In the 90s, the company stopped baking. Unilever took over the factory in 1985 and started producing Ola ice cream. Since 2002, the core business of the factory has been producing Ben & Jerry's ice cream. Ben & Jerry's is a great example of a factory where all kinds of brownfield-projects run and have been run in order to produce in a state of the art manner.

.jpg)

In the reception hall, we meet Leon ter Braak—QA Officer at Ben & Jerry's Hellendoorn— who has worked at this location for 17 years. We take our seats in the Strawberry Cheesecake room. The smaller Peanut Butter room was occupied. Smaller? Yes, but the peanut products are more popular. Leon has just completed a validation of the factory as one that produces products with and without peanuts.

Leon explains that the work of a QA Officer involves many things. FSSC 22000 requires that necessary measures are implemented with regard to food fraud and food defense. The entrance gate was moved, a fence was placed around the building, and identification was required upon entry. ‘Cleaning and disinfection’ were also an important part of the FSSC 22000. However, appropriate measures were already in place because milk and milk free products were produced on the same production line.

Hygienic design? The FSSC 22000 is not specific in this area. Leon points out: "You trust that the supplier of the machines will supply them in accordance with the EHEDG Guidelines. Of course, the machines are tested and assessed before use by our Project Engineers. We see that most issues arise with our own in-house modifications to the machines.”

In regard to food safety, quality concerns always revolve around four things: microbiology, allergens, chemistry and foreign parts. There is always something to improve. An example is the current way in which cables are attached to the equipment. It is not easy to clean around cabling—a prerequisite for controlling microbiology. Cable ties become brittle and break over time due to frequent cleaning. Pieces of cable ties, including the metal detectable ones, cannot always be detected. Yet, Leon cannot recall ever having received a complaint about this. Nevertheless, you always want to prevent it from happening.

Recently, Leon attended a Knowledge Event on Hygiene in the Food Industry, organized by Safe Food Factory and held at the Technische Unie. Leon went with the idea that “this can be interesting, even though I may not have the technical knowledge”.

The alternative of securing cables with a spring instead of cable ties, which was presented at the event, was a good idea to implement at the factory. The Quality Department manages the improvements at Ben and Jerry's Hellendoorn and has a dedicated budget for this. A team was formed immediately, and Gouda Holland (part of the Niedax Group) was invited to give an in-house presentation together with the line engineer involved. "When he recognized the practical benefit as well, he submitted the idea to the MT and they approved it," said Leon. "Now the first three items have been placed on one of the machines at a critical location above the six open packages. The first steps have been taken. Two cables still need to be extended and other parts like cable trays need to be adjusted too, but priority is given to the inside of the equipment. The first reactions are positive. It looks sleek. The cables run neatly, and you have room to clean”.

Saving by investing. Leon explains; "Upgrading an existing installation with Streamline HD will pay for itself. It makes the installation more flexible and easier to maintain. This just saves the Technical Department a lot of time and work".

What does the future look like? Leon continues; "I really like the solution from our supplier Selo for new equipment. The last unit Selo had not wired in this way. Selo now consistently applies the new cabling method throughout each machine. We are also going to make this wiring method compulsory for new equipment - and step by step, we are going to renew existing installations.”

Featured expert: Michael Evers