Meat croquette

Meat croquettes are a typical Dutch snack. A croquette is a deep-fried product which consists of a provided ragout, which is coated with a thin layer of breadcrumbs. This breading layer consists of egg wash and breadcrumbs and ensures that the content of the croquette is held together during the deep-frying. Nowadays croquettes available in many variants, such as the potato croquette, goulash croquette and cheese croquette. The majority of these industrially manufactured croquettes are frozen.

Croquette production

Raw materials

According to the Dutch Commodities Act, croquettes may, in addition to water (62 to 72%), contain ragout, wheat flour (± 10%) and a maximum of 10% fat. In addition, the ragout has to contain at least 5 to 20% meat, depending on the croquettes quality indication. Only meat of high quality, with a low fat content and a very low collagen/protein ratio, is included when measuring the meat content.

Usually, South American frozen horse meat is used for the croquette filling. These blocks of meat are chopped into pieces and defrosted at a temperature of 4°C. The defrosting can take 1 to 2 days.

It is important that the egg wash mixture coagulates in the right way during frying, holding the breadcrumbs together, forming a coating around the ragout. Breadcrumbs may contain up to 12% moisture and must have a sufficiently voluminous grain structure so that sufficient moisture can be absorbed during cooking.

Roux Preparation

To prevent lumps from forming during the mixing of the flour and water, the flour is first mixed with melted fat or oil at a temperature of from 90 to 120°C. The roux has to form a homogeneous mass, because it determines the consistency of the final product. When this mixture is then mixed with a portion of the water phase, a better gelatinization of the starch will take place.

Making Stock

A broth is made from the meat with water. This is done at a temperature of between 70 and 95°C and can take up to 24 hours. Automated ragout boilers are often used for this process. The meat is then separated from the broth.

Grinding the meat

After a check on irregularities has been performed, the meat is reduced using a meat grinder. Ensuring that the meat is not made smaller than 0.85 mm, otherwise the meat does not count towards the meat content measured using a special method, in Dutch the so-called ‘pluis’ method. This method involves the croquette being stripped from its breadcrumb outer layer and the remaining part being cooked. Next, the whole, together with the hot water, is sieved through a sieve with a mesh size of 0.85 mm. Non-meat parts are removed and what is leftover makes up the coarse total meat content.

Mixing

In a boiler with agitators, the broth is mixed with the roux preparation, making the roux fully absorb the broth. The mixture is then heated to 80°C, creating a viscous mass through the gelatinization of the starch. It is possible to lower the viscosity by continuing stirring for some time. Then, the meat, herbs, thickeners, and any pre-cooked vegetables added to the mixture.

In order to avoid a too strong reduction of the cooked meat, the post-mixing step must be as short as possible.

Cooling

The ragout is then filled into flat stainless steel trays and placed to cool down to a temperature of 4°C in a cold storage room. The cooling takes at least 24 hours, allowing the ragout to develop its flavor. In addition, there is the possibility to fill the ragout in plastic casings and allowing them to cool in running water, after which they are further cooled down in a cold storage room.

However, it is better to cool the ragout using a scraping heat exchanger, preventing microorganisms from growing, and accelerating the process. During cooling, the viscosity increases because of retrogradation of the starch.

Shaping

After cooling, ragout balls are formed using a portioning machine. The ragout balls fall on a treadmill and are formed into the croquette shape here. A vacuum filling machine can also be used to shape the croquettes. The molding plates are sprayed beforehand with water of 0°C, which will prevent the ragout from sticking.

Flouring

The ragout shapes are floured. Flouring involves sprinkling the croquettes with wheat flour, after which part of the flour is blown off in order to remove the excess flour. Flouring limits shrinkage during baking and makes the egg wash attach better.

Breading

In order to make the breading layer stay in place and form a crispy crust, the croquettes are provided with a layer of egg wash. This wash consists of vegetable protein, starch and a thickening agent.

The outer layer of the croquette consists of a breading layer. The breading layer is made from fresh bread or biscuits and may differ in color and flavor. The fat absorption of the croquette during frying when using coarse breadcrumbs (> 0.5 mm) is higher than when using fine breadcrumbs. However, coarse breadcrumbs are used more often. Because they provide the croquettes with a crispier crust.

Freezing

In order to increase the shelf life of the meat croquettes, they are frozen. One could choose to hand pack the croquettes before freezing them. The croquettes are put in boxes and stacked on a cart placed in a freezer room.

Nowadays the croquettes are generally frozen to -18°C or lower before packing. This can be done using a spiral freezer, or by the cryogen freezing. When using cryogenic freezing, liquid nitrogen, with a temperature of -196°C, is sprayed over the product. The warmed nitrogen vapors are then filtered off with suction. Using this method, the croquettes can be frozen to -18°C within 15 minutes. Due to the fast freezing, there is less loss of the water binding capacity of the proteins in the croquette.

Packing

After freezing the croquettes generally are hand-packed in cardboard boxes. a sheet of waxed paper can be put at the bottom and in between each layer of croquettes, preventing the croquettes from freezing together. To counter temperature fluctuations during distribution and storage, the croquettes are deep-frozen to -20°C and kept at this temperature.

Food Safety & Hygienic Design

Meat is an excellent environment for the growth of pathogenic microorganisms. It is therefore important to keep the temperature low. This applies for the product, but also for the environment. A temperature of 4°C is preferred.

If because of the operating personnel a higher temperature is set, for example 8 to 12°C, the tools and materials that come in contact with the meat have to be changed every 2 to 4 hours.

The ragout undergoes a heat treatment step, in which all the vegetative microorganisms are killed. When the product is at a temperature between 70 and 7°C, the equipment must meet the requirements of hygienic design - being cleanable to microbial level. A 4-hour cool-down time to 7°C will not cause any significant microbial growth.

If the croquettes are pre-fried, and then frozen, the risk arises that during the cooling process by air, microbial growth takes place in the air cooler, which will contaminate the product. This has happened with ‘frikadellen’, containing the S. aureus in high numbers, which were later killed off in the fryer, but the heat-stable toxin of this microorganism still caused food poisoning.

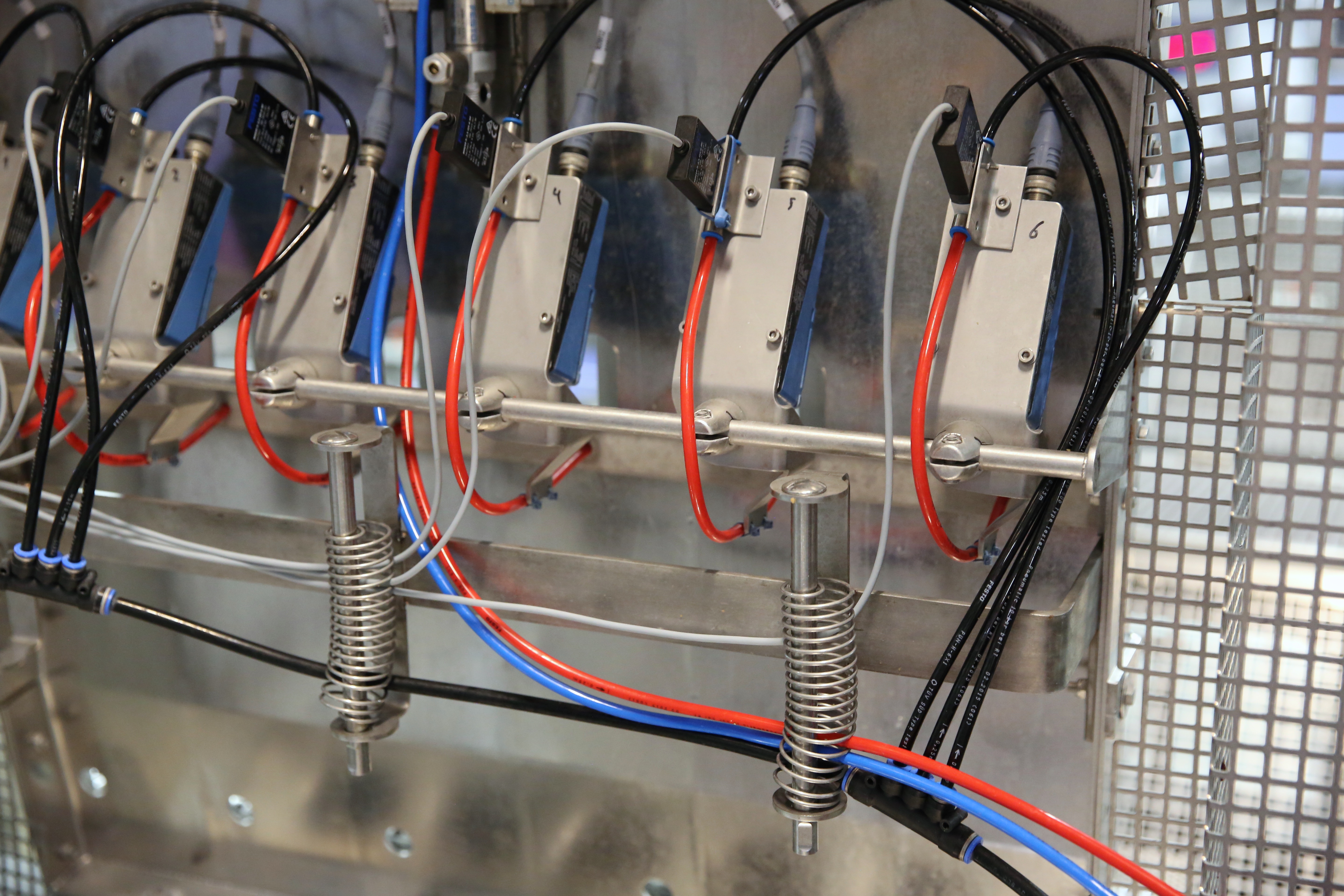

Hygienic cabling at a Unilever factory

The Streamline HD cable support system was explained at a knowledge event. After internal consultation, Ben & Jerry's decided to get started with it. The initial findings are so positive that they are going to prescribe their suppliers to use this form of cabling from now on.

“My boys were quite envious when they heard where I was going”, Michael Evers—Business Development Manager at Niedax Group and Secretary of the national working group Hygienic Cabling— told us, while standing in the reception hall of Ben & Jerry’s factory in Hellendoorn.

It all started in the 1950s; in addition to bread and pastries, Hellendoorn baker Gerrit Valk, decided to start producing ice cream. In the 70s, the production site was moved from the centre of Hellendoorn to its current location in Hellendoorn, and was increasingly automated. In the 90s, the company stopped baking. Unilever took over the factory in 1985 and started producing Ola ice cream. Since 2002, the core business of the factory has been producing Ben & Jerry's ice cream. Ben & Jerry's is a great example of a factory where all kinds of brownfield-projects run and have been run in order to produce in a state of the art manner.

.jpg)

In the reception hall, we meet Leon ter Braak—QA Officer at Ben & Jerry's Hellendoorn— who has worked at this location for 17 years. We take our seats in the Strawberry Cheesecake room. The smaller Peanut Butter room was occupied. Smaller? Yes, but the peanut products are more popular. Leon has just completed a validation of the factory as one that produces products with and without peanuts.

Leon explains that the work of a QA Officer involves many things. FSSC 22000 requires that necessary measures are implemented with regard to food fraud and food defense. The entrance gate was moved, a fence was placed around the building, and identification was required upon entry. ‘Cleaning and disinfection’ were also an important part of the FSSC 22000. However, appropriate measures were already in place because milk and milk free products were produced on the same production line.

Hygienic design? The FSSC 22000 is not specific in this area. Leon points out: "You trust that the supplier of the machines will supply them in accordance with the EHEDG Guidelines. Of course, the machines are tested and assessed before use by our Project Engineers. We see that most issues arise with our own in-house modifications to the machines.”

In regard to food safety, quality concerns always revolve around four things: microbiology, allergens, chemistry and foreign parts. There is always something to improve. An example is the current way in which cables are attached to the equipment. It is not easy to clean around cabling—a prerequisite for controlling microbiology. Cable ties become brittle and break over time due to frequent cleaning. Pieces of cable ties, including the metal detectable ones, cannot always be detected. Yet, Leon cannot recall ever having received a complaint about this. Nevertheless, you always want to prevent it from happening.

Recently, Leon attended a Knowledge Event on Hygiene in the Food Industry, organized by Safe Food Factory and held at the Technische Unie. Leon went with the idea that “this can be interesting, even though I may not have the technical knowledge”.

The alternative of securing cables with a spring instead of cable ties, which was presented at the event, was a good idea to implement at the factory. The Quality Department manages the improvements at Ben and Jerry's Hellendoorn and has a dedicated budget for this. A team was formed immediately, and Gouda Holland (part of the Niedax Group) was invited to give an in-house presentation together with the line engineer involved. "When he recognized the practical benefit as well, he submitted the idea to the MT and they approved it," said Leon. "Now the first three items have been placed on one of the machines at a critical location above the six open packages. The first steps have been taken. Two cables still need to be extended and other parts like cable trays need to be adjusted too, but priority is given to the inside of the equipment. The first reactions are positive. It looks sleek. The cables run neatly, and you have room to clean”.

Saving by investing. Leon explains; "Upgrading an existing installation with Streamline HD will pay for itself. It makes the installation more flexible and easier to maintain. This just saves the Technical Department a lot of time and work".

What does the future look like? Leon continues; "I really like the solution from our supplier Selo for new equipment. The last unit Selo had not wired in this way. Selo now consistently applies the new cabling method throughout each machine. We are also going to make this wiring method compulsory for new equipment - and step by step, we are going to renew existing installations.”

Featured expert: Michael Evers