Aire Comprimido - un riesgo de contaminación oculta (EN)

La presencia de lubricante de compresor de aire en aire comprimido

La lubricación es necesaria para el funcionamiento de un compresor de aire suave y eficiente. Sin embargo, es posible el contacto entre el aire comprimido y el lubricante, de modo que la niebla de aceite pueda entrar en el aire. El reemplazo por compresores libres de aceite puede evitarse cambiando al lubricante de calidad alimentaria especialmente desarrollado para compresores. Como resultado, es posible, en caso de contacto, mantenerse dentro de las normas de la FDA, mientras que el funcionamiento del compresor puede incluso mejorar. Nota: Fuchs Lubricants se ha hecho cargo de Shell Lubricants.

The presence of air compressor lubricant in compressed air can be a major area of concern for food & beverage manufacturers. Commonly used in food processing plants, compressed air is used to mix liquids and provide safe power delivery for critical tasks in areas such as material transport, filling lines, spray applications and drying. However, as the majority of air compressors are oil lubricated, food safety can be quickly compromised by the use of non-food grade compressor oils.

Essential to the smooth and efficient running of air compressors, lubricating oils help to reduce metal-to-metal contact between the compressor’s rotor or helicoidal screws and the cylinder housing. This helps to minimise expensive component wear and damage, reducing unplanned downtime and enabling operators to realise the low maintenance and reliable performance benefits of compressors. As compressors operate in close proximity to food stuffs, there is a realistic threat of accidental oil contact, which is why Shell lubricants companies have developed a new food grade compressor oil.

Oil Mist Risks

Oil mist can form in compressed air as a result of high operating temperatures and can be difficult to detect. This increases the threat of the oil mist coming into direct contact with food; a problem that can easily go unnoticed until detected by the consumer. By this time though, it can be too late, as consumer health and welfare has been jeopardised. This can bring the company under public scrutiny, which can severely impact on long-term market performance and survival.

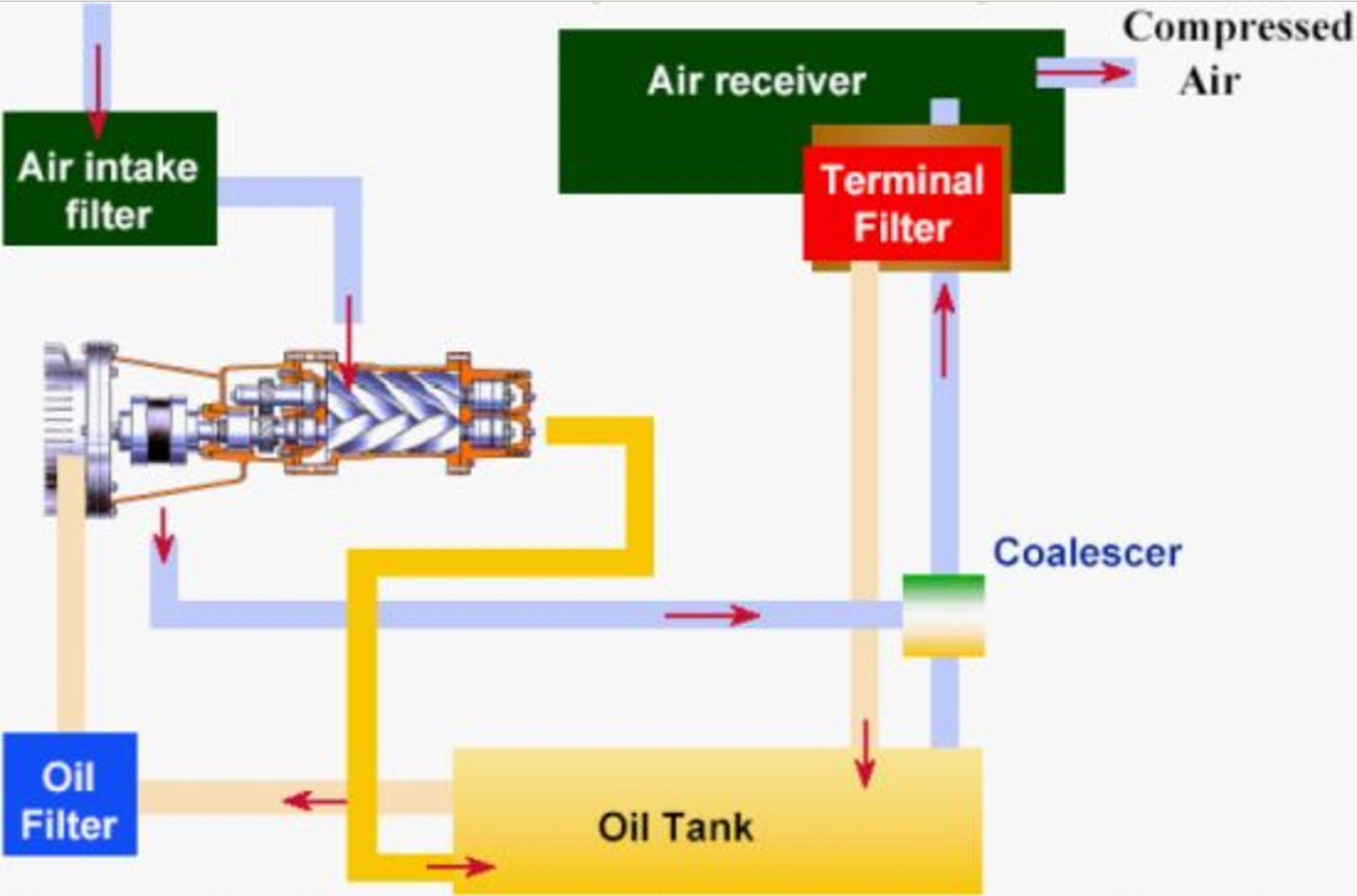

The amount of oil in compressed air depends on a number of factors, including the condition of the machine and how regularly it is maintained, the condition of the coalescer and filters and whether parts that have been fitted have been recommended by the original equipment manufacturer. Other risk factors include the age of the compressor oil, whether the correct oil is being used and whether secondary filters have been fitted. Failure to maintain and regularly replace filters will also increase the risk of contamination.

As Figure 1 shows, even when using multi-stage filtration, there is still a risk of contamination with food as oil particles remain in the compressed air. While a multi-filter system can reduce oil mist concentration to as low as 0.1 parts per million (ppm), it is impossible (under normal conditions) to remove 100 per cent of oil mist for an end result of 0.0ppm – the maximum tolerance of non-food grade lubricant contamination with food and beverages allowed by the US Food and Drug Administration (FDA).

Fig. 1. It’s impossible to remove 100% of oil mist

Reducing Contamination

While it is possible to avoid the presence of an oil mist by using an oil-free compressor, this is an expensive option requiring replacement of existing non-oil free compressors. A much more cost-effective solution for operators is the use of food grade compressor oils. Specifically developed for use in air compressors, high quality, synthetic, H1 approved, food grade compressor oils such as Shell Cassida ® Fluid CR 46 have been formulated using approved additives and base fluids. This composition means that Shell Cassida Fluid CR 46 is tasteless, colourless and odourless and will not contaminate food in quantities less than the US FDA’s maximum permitted level for H1 lubricants of 10 parts per million.

Fully registered by the NSF as H1 for incidental food contact, Shell Cassida Fluid CR 46 is a fully synthetic oil that can increase food safety and compressor performance. Cassida Fluid CR 46 has excellent high temperature resistance to oxidisation, which reduces gum and lacquer deposits on the coalescer, reducing filter saturation and the risk of oil mist. As well as improving air quality, the reduction in deposits enables better fluid circulation and lubrication of the compressor, improving efficiency and lowering maintenance costs.

Cassida CR 46 – Food Grade Performance

Atlas Copco oil-flooded GA 37 screw compressor, after 5,756 hours

Clean Coalescer will remove oil mist efficiently

Oil Filter Mounting Plate: no sign of oil oxidation

This compressor was running on a competitor fluid, which showed deposits before the oil change at 4,000 hours. It was flushed and filled with Shell Cassida Fluid CR 46. After 5,756 hours on Shell Cassida Fluid CR 46, the coalescer and oil filter were inspected with the following results:

- Both were found clean and free from deposits

- Seals were in excellent condition

- Oil Analysis showed oil still in excellent condition

(oil should be analysed periodically)

Shell Cassida CR 46 has been used in these compressors:

Atlas Copco, Berko Compressors, Compair Hydrovane, Gardner Denver, Grassair, Hitachi Compressors, Ingersoll Rand, Rietschle, Vemag Maschinenbau GmbH.

Food Grade Benefits

Although the risk of compressed air contamination is difficult to detect, the consequences are much more visible…. especially on the bottom line. Excessive costs can be incurred as whole batches of contaminated food are destroyed and unadulterated products recalled. Furthermore, production lines may have to be completely stopped as the contamination incident is rectified and compressors cleaned.

High quality, synthetic, food grade lubricants such as Shell Cassida CR 46 can help operators to maintain cleaner air and improve food safety levels, reducing the adverse impact of oil mist contamination. These safety benefits are supported further with excellent compressor oil performance, which can lead to extended oil drain intervals, meaning that operators do not have to make a choice between performance and safety.

Content of Practical Guideline Hygienic compressed air in the food industry (EN)

A continuación encontrará una descripción general del contenido de la Guía práctica "Aire comprimido higiénico en la industria alimentaria" (en inglés). Para obtener acceso, debe crear una cuenta e indicar durante el registro que desea acceder a las pautas. Eso cuesta 125 euros, = por año excl. TINA. Si ya tiene una cuenta, puede enviarnos un correo electrónico y comenzaremos el procedimiento para darle acceso. La publicación en inglés seguirá pronto.

Working group members

René Bakker, RMB Consultancy (previously Hago Food & Industry).

Wouter Burggraaf, Burggraaf & Partners (chairman).

Maurice van Dam, Parker Hannifin (later succeeded by Michael Matthijssen).

Michael Evers, Niedax (secretary).

Jef Goossens, Boge Kompressoren B.V.

Christoph Illing, Parker Hannifin.

Edwin Lamers, Bürkert.

Koen Leeflang, Festo B.V.

Michael Matthijssen, Parker Hannifin.

Johan Nooijen, Geveke.

Norbert Rozemeijer, Ants Technology & Consulting

Roy Schep, SMC Pneumatics BV (successor of Henk Klein-Middelink and Gert-Han Konijn).

Pieter van der Schepop, Fuchs Lubricants (ad hoc member).

Herman Steen, Synamic.

Martijn Visser, previously Adsensys B.V.

Mark White, Parker Hannifin (ad hoc member).

1 Scope

The practical guideline Hygienic compressed air in the food industry deals with the hygienic aspects of

- compressed air (from outside air to consumption point)

- including all conditioning, design, verification and monitoring

- including recommendations for energy consumption reduction

for application in the food industry.

Part of the guideline is a substantiation of the hazard and risk analysis.

2 Normative references (legislation and regulations)

There are three food safety laws that need to be considered in the EU:

- Hygiene regulation Reg. 852/2004

- Machinery Directive (2006/42 / EC)

- Materials regulations Vo1935 / 2004; Vo10 / 2011

And for (breathing) air (intensive contact with (pressurised) air)

- Directive on personal protective equipment

The FDA Code of Federal Regulations applies to the United States.

The standards for compressed air, driers, filters, appendages and hoses have been taken into account when drafting the guideline.

In addition, the other practice standards have also been considered: BRC v7, IFS v6, 3-A and more.

3 Terms and definitions

Own definitions, concepts from guideline EN 1672-2 and zone classification.

4 Compressed air installation - Principles

Overview of the components that make up a compressed air system, with attention to the different principles and variants that can be chosen for a component: compressor or blower, oil-lubricated or oil-free, kind of separators, after-coolers, dryers, and filtering and separation steps.

5 Risk analysis

It discusses what can be significant hazards to the food, which can come with compressed air. This yields a number of sources that are treated individually:

- (aspirated) ambient air

- suction filter

- air compressor

After the compression:

- wet air buffer

- dryer

- filter

And finally:

- storage and distribution

The risks are discussed per source, such as

- water vapour and condensate

- particulate matter

- micro organisms

- environmental dirt

- hydrocarbons

- fragrances and flavours

- chemicals

- nutrients

- lubricating oil and grease

- dust formation by adsorbent.

Then recommendations are made for removing these hazards by source.

Where complete prevention of the hazard is not possible, the risks must be limited. It is indicated to which limits the compressed air must comply in terms of micro-organisms, moisture and the various contaminants.

6 Design requirements

In this chapter, the compressed air system is followed from intake to consumption point, and criteria and recommendations are given.

7 Verification & monitoring

Discussion of verifications of filters and of some quality characteristics of compressed air: residual moisture, residual oil, particles and microorganisms, and what measurement methods are available for this.

8 Recommendation

A brief overview where energy-saving measures are possible.

9 Working visits

The visits and discussions that the working group has held.