¡El coronavirus! ¿Cómo pudo llegar tan lejos...? (EN)

Air hygiene is crucial in controlling virus spreading. Lowering the virus load decreases the infection rate significantly. The current air refreshment systems pose a danger, but can be improved. Air flow simulations and tests show results and applications are already in place.

Introduction

The corona crisis proofs what we have been saying for 20 years - Air hygiene is - besides washing hands, clean clothes, etc. - the last piece in a closed hygiene concept. It made the latent need shift into an urgent need.

Unfortunately, it also shows that because of the latent need for air hygiene, legislation has never really come up with regulations that would have spurred companies to pursue innovation or direct solutions – reason why we are all now so "panicking” when asking:

- How does the virus spread?

- Is it airborne?

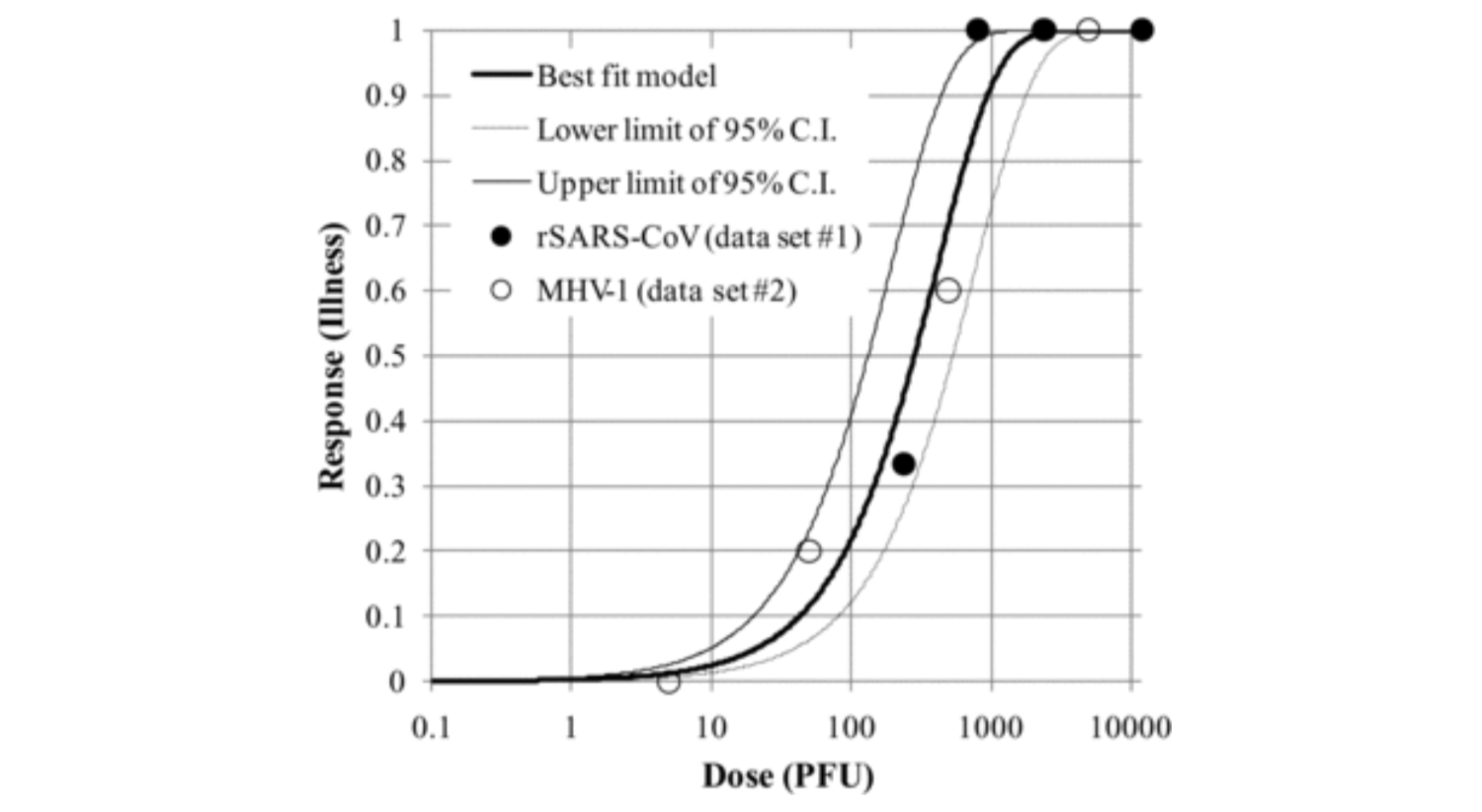

- How many viruses are needed to have an infection propagate (Dose-Response relation)

Meanwhile we now know how the virus can spread and what measures it could limit its spreading:

- Direct (droplet) contact (1.5 m, wearing masks and fever measurements)

- Inhaling aerosols (increase ventilation, increase humidity and more UV-C air disinfection)

- Smear infections (surface and hand disinfections)

- HVAC recirculation risk (apply UV-C in air ventilation system)

Infection prevention

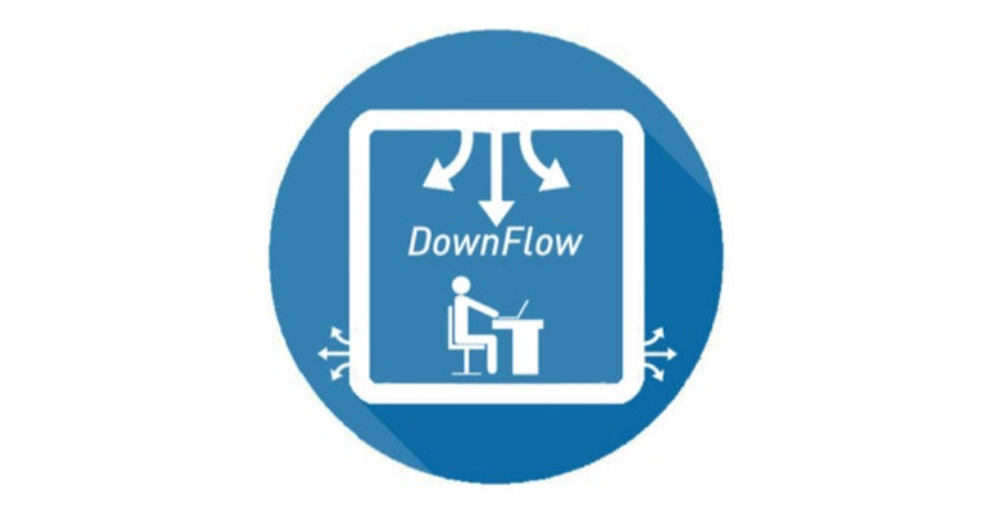

Infection prevention requires 1) clean air, but also that the clean air 2) follows the right path; namely in such a way that it keeps polluted air away from humans. In practice, this is nothing new, since we already do this in operating theatres and call it DOWNFLOW SYSTEMS.

Here is a brief explanation:

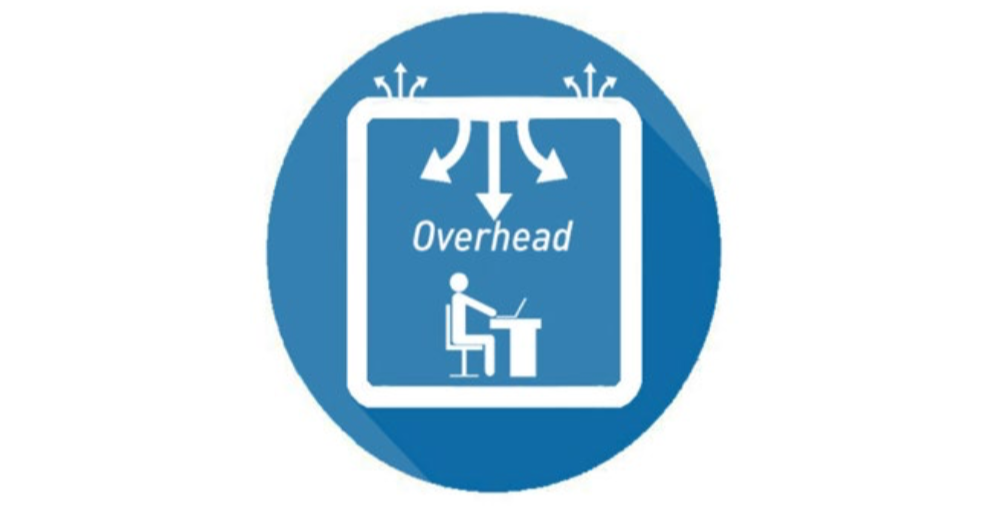

It is standard practice in offices to use a so-called overhead system. Air is blown at the (dropped) ceiling and also extracted at the (dropped) ceiling.

| (+) | (-) |

|---|---|

| Execution in practice | More air than needed due to short-circuit |

| Low CADR* | |

| Virus Aerosol unsafe |

| *) CADR: Clean Air Delivery Rate. The CADR determines the degree of short circuit between supply and exhaust air (grids). Clean air is often extracted directly. |

Hygienically, this is a disaster, because you spread the virus (aerosol) to all people. It is therefore better to use a downflow system, which “pushes” all virus aerosols to the ground and extracts them there.

| (+) | (-) |

|---|---|

| Virus Aerosol safe | Comprehensive execution in practice |

| Very good CADR |

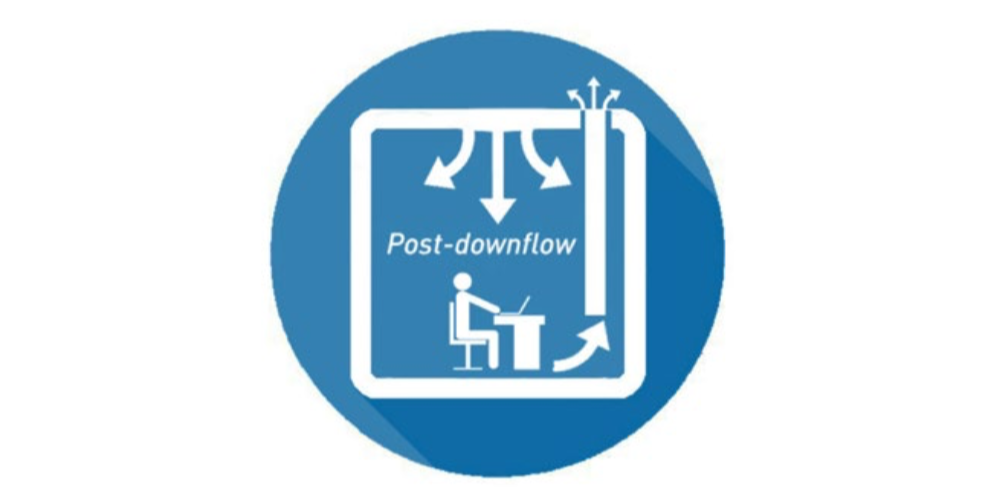

The objective is therefore to convert an overhead system of offices, schools, concert halls, etc. into a downflow system in order to offer absolute safety. This can be done relatively easily by moving the existing (ceiling) exhausts to a point 30 - 40 cm above the floor.

Computer simulations

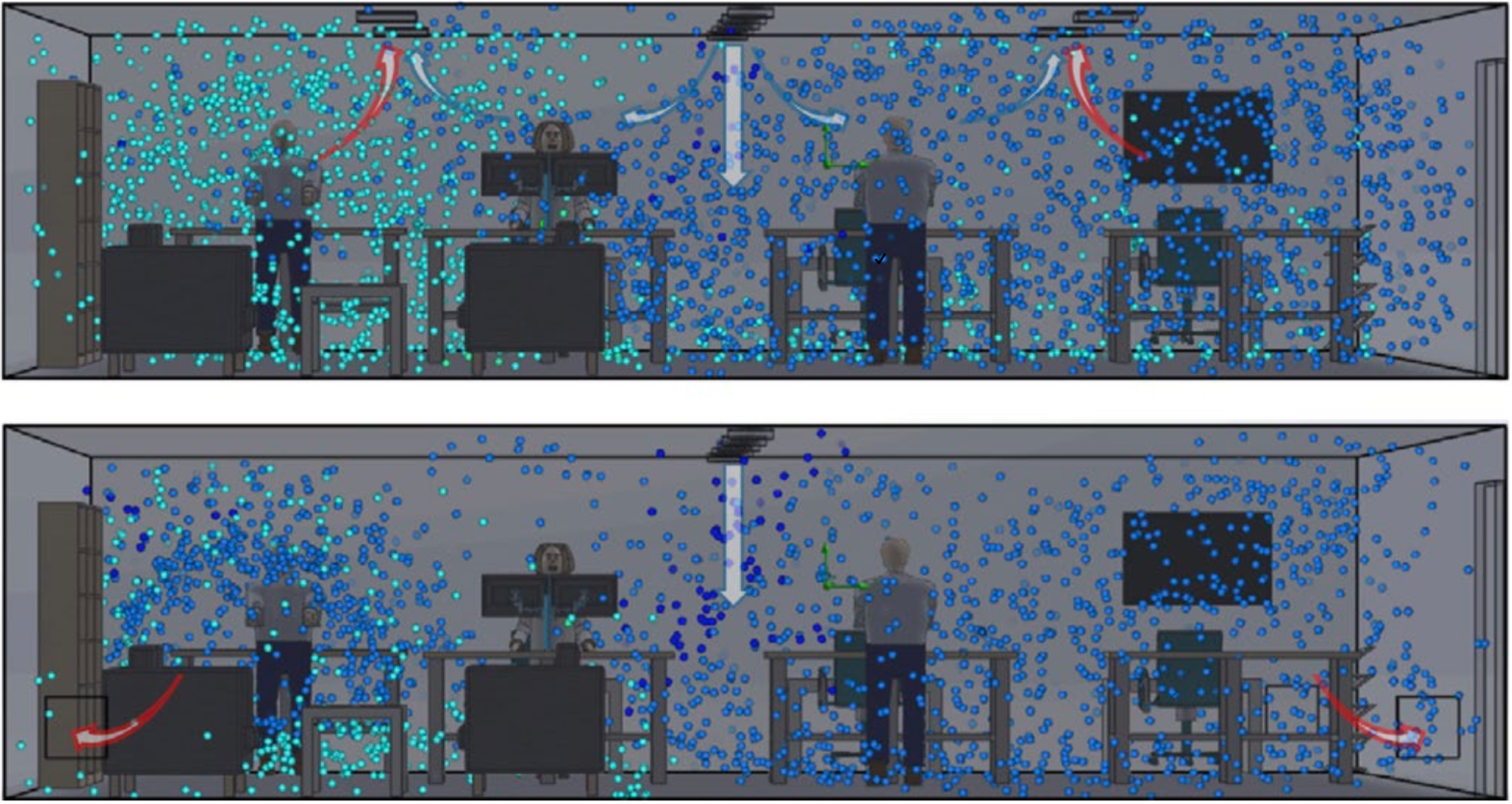

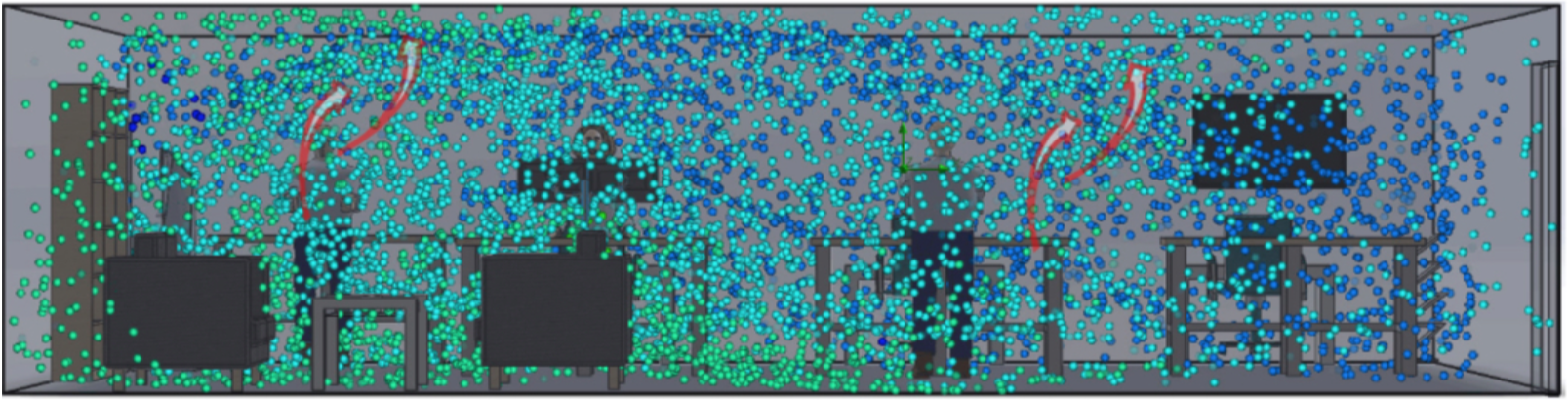

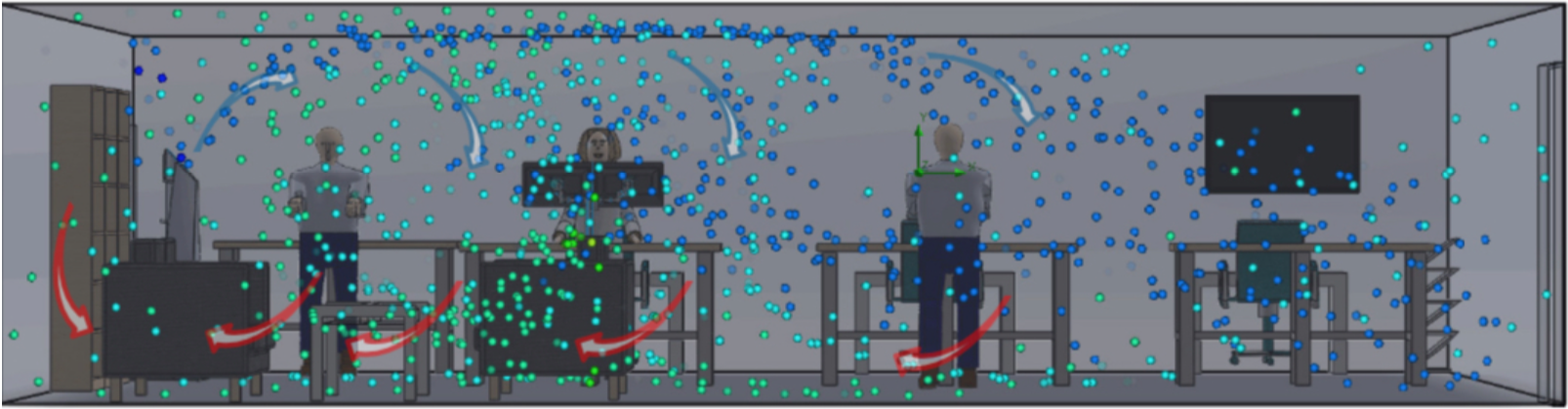

Computer simulations show the difference in safety also:

Lady continuously spreads (green) virus particles.

The next 2 pictures show the movement of the air in case of an overhead system and the movement of the air after conversion to a post-downflow system.

Left: Air (and virus aerosol) rises, indicated by the smoke following the red arrow.

Right: Air (and virus aerosol) is forced downwards and removed via the newly installed exhaust; smoke follows green arrow.

Virobuster International GmbH

Virobuster have been established in 2002 and initially developed successfully the medical market before entering the food production industry.

The Steritubes are produced at the German JK-Group. The JK- Group has its production facility in Germany and is DIN, ISO and TÜV certified.

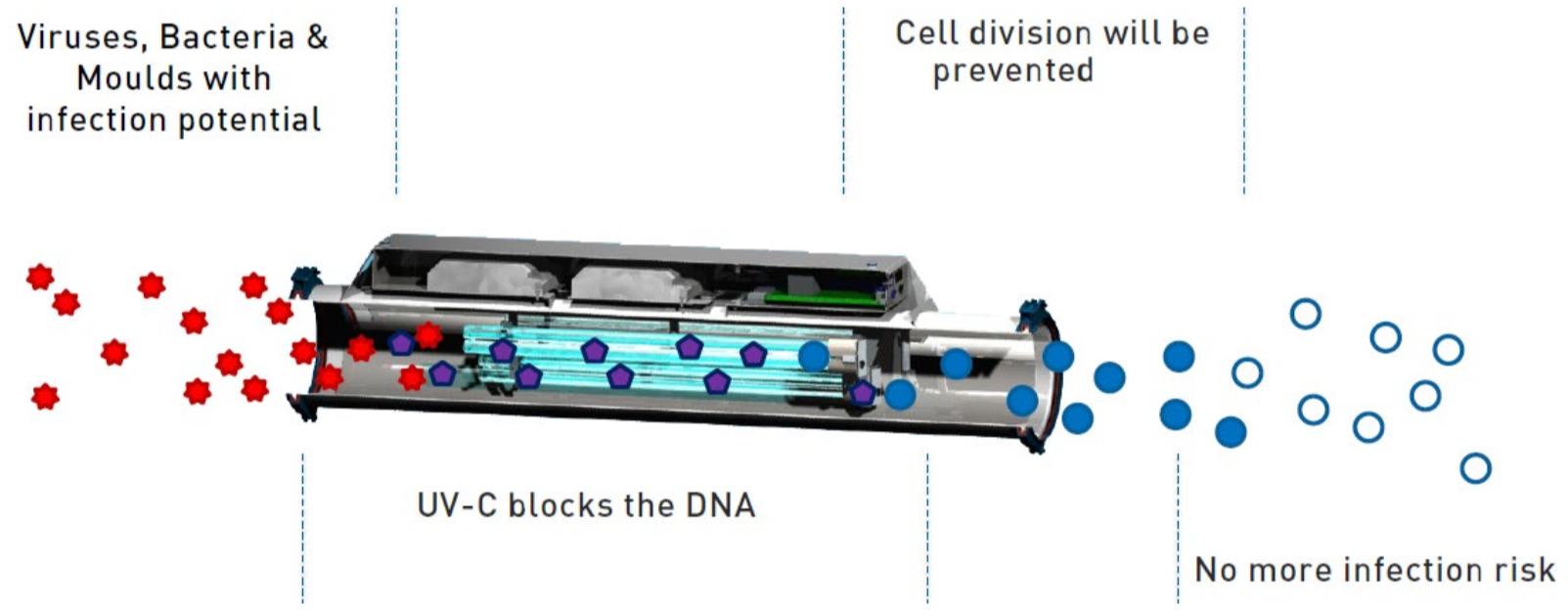

UVPE (Ultra Violet Pathogen Elimination)

The air is guided through the UVPE field. The DNA of the micro-organism is blocked (thymine blocking), preventing future cell division and making the micro-organism harmless (medical: not infectious anymore, Industrial: no product decay anymore).

The doses needed for sufficient deactivation depends on the type of organism, the intensity - and the residence time in the UV field.

“Clean Air makes the difference”

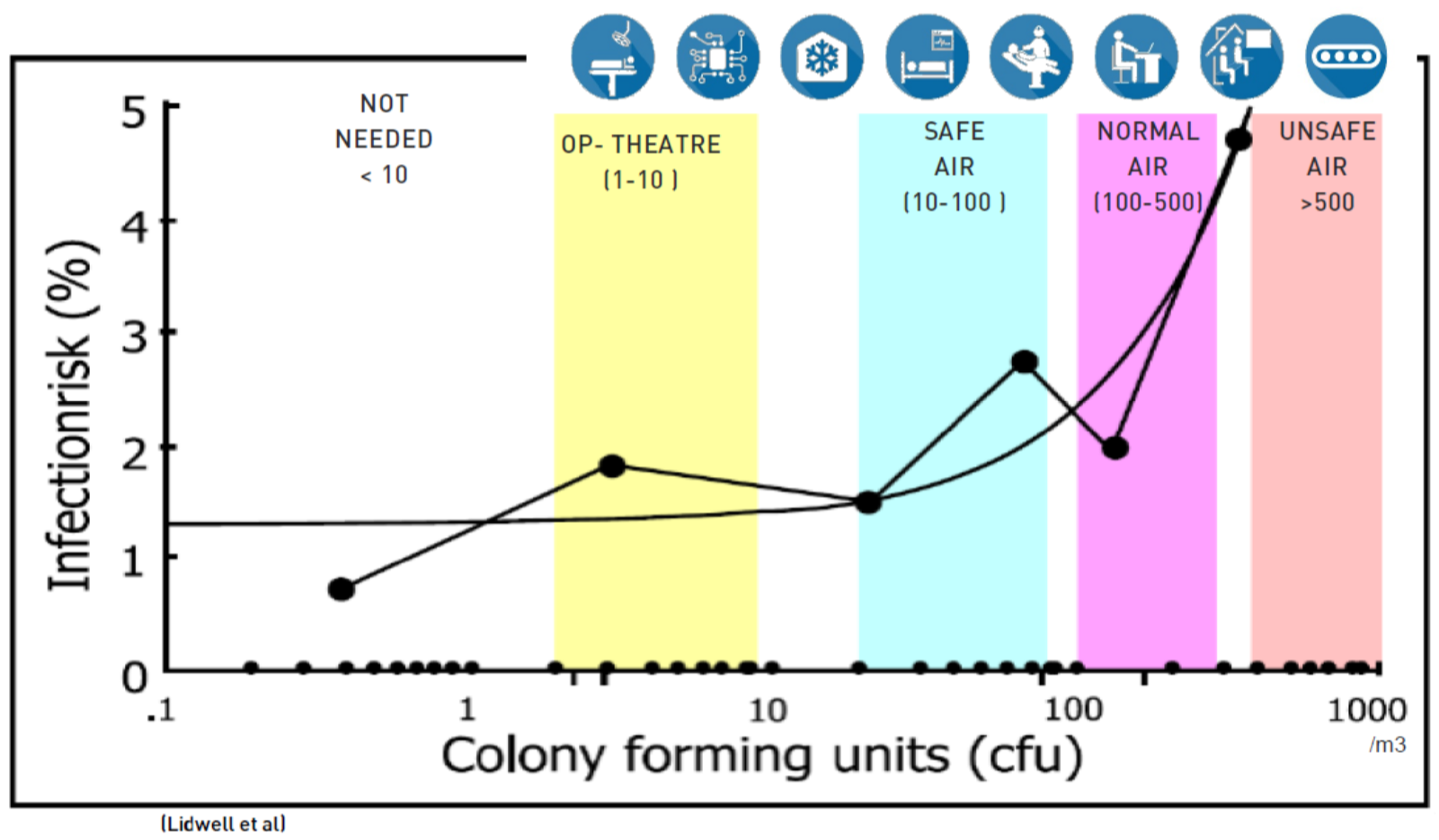

A reduction from 1,000 CFU to 100 CFU (10 CFU), results in a decrease of infection risk of 60% (74%) – Lidwell et Al, Lindqvist et Al.

The reduction of micro-organism in the air means a significant decrease of infection risk among patients and increased safety for medical staff. The corona Virus shows also a dose-response relation (PFU vs Infection risk).

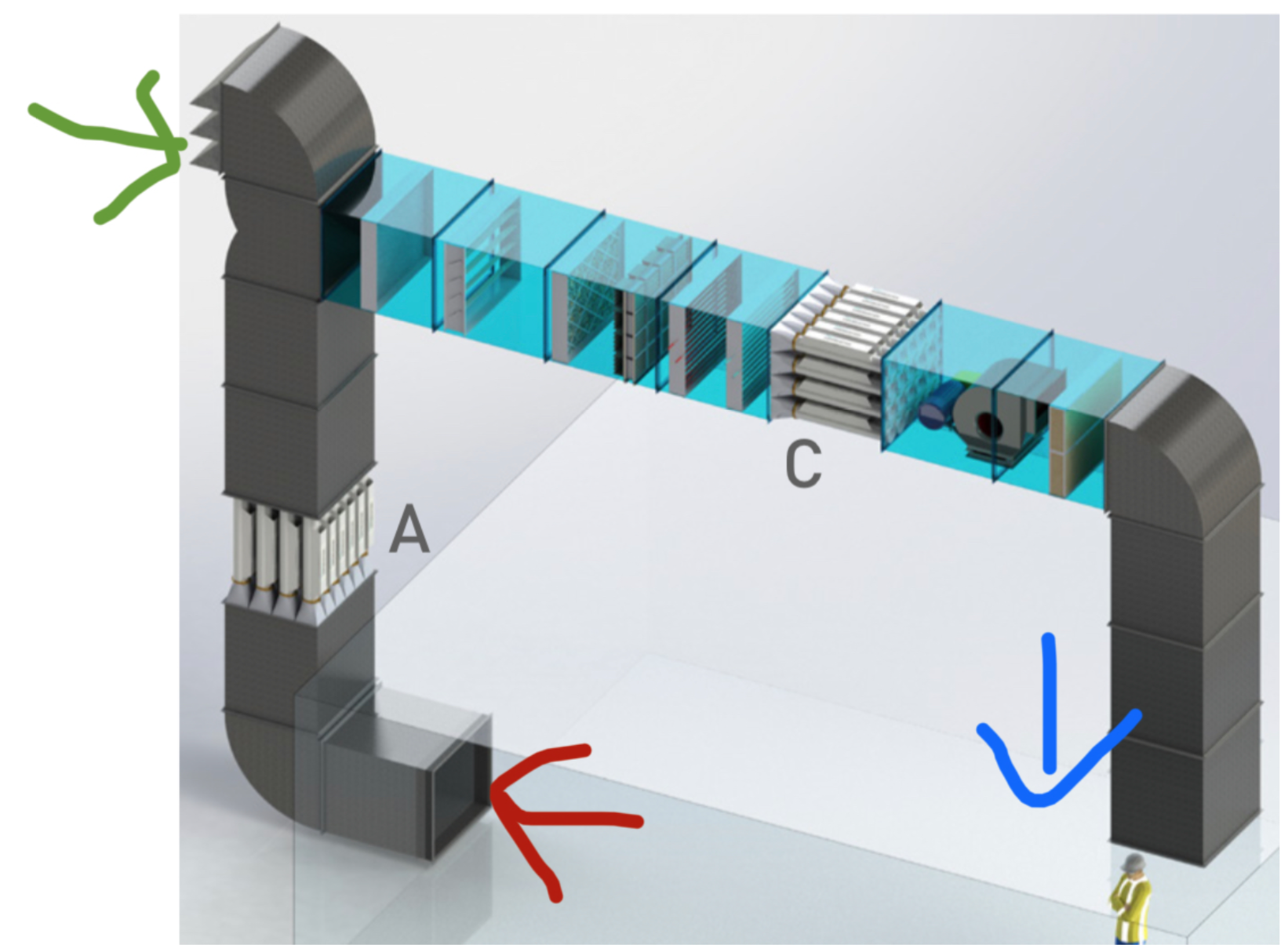

HVAC Air treatment using Virobuster UVPE (Steritube) modules.

Next to the air quality question, the second question that may now be asked is; how do we clean the air with Virobuster Steritubes? Ideally return it and not to use too much energy by using only 100% fresh outside air. There are so-called heat exchangers for this, but they have the risk that they partly return the virus to the user due to the carry-over effect.

THE solution is to implement Virobuster Steritubes into the ventilation system.

Green = outside air, red = virus-loaded extracted air and blue conditioned and safe air to the user.

The Steritubes can be placed in the return duct(A) or in the total supply (duct/AHU) (C). This depends on whether the fresh supply air also carries the virus risk.

Air treatment with Stand-Alone units

In practice, however, there are also many buildings (schools, waiting rooms, small offices, etc.) that do not have a HVAC ventilation system and rely on heating with radiators and "split air conditioners" for the summer. Ventilation is done through windows or grilles in the windows / walls.

Split airco where the air is only cooled, and not (or very small part) refreshed.

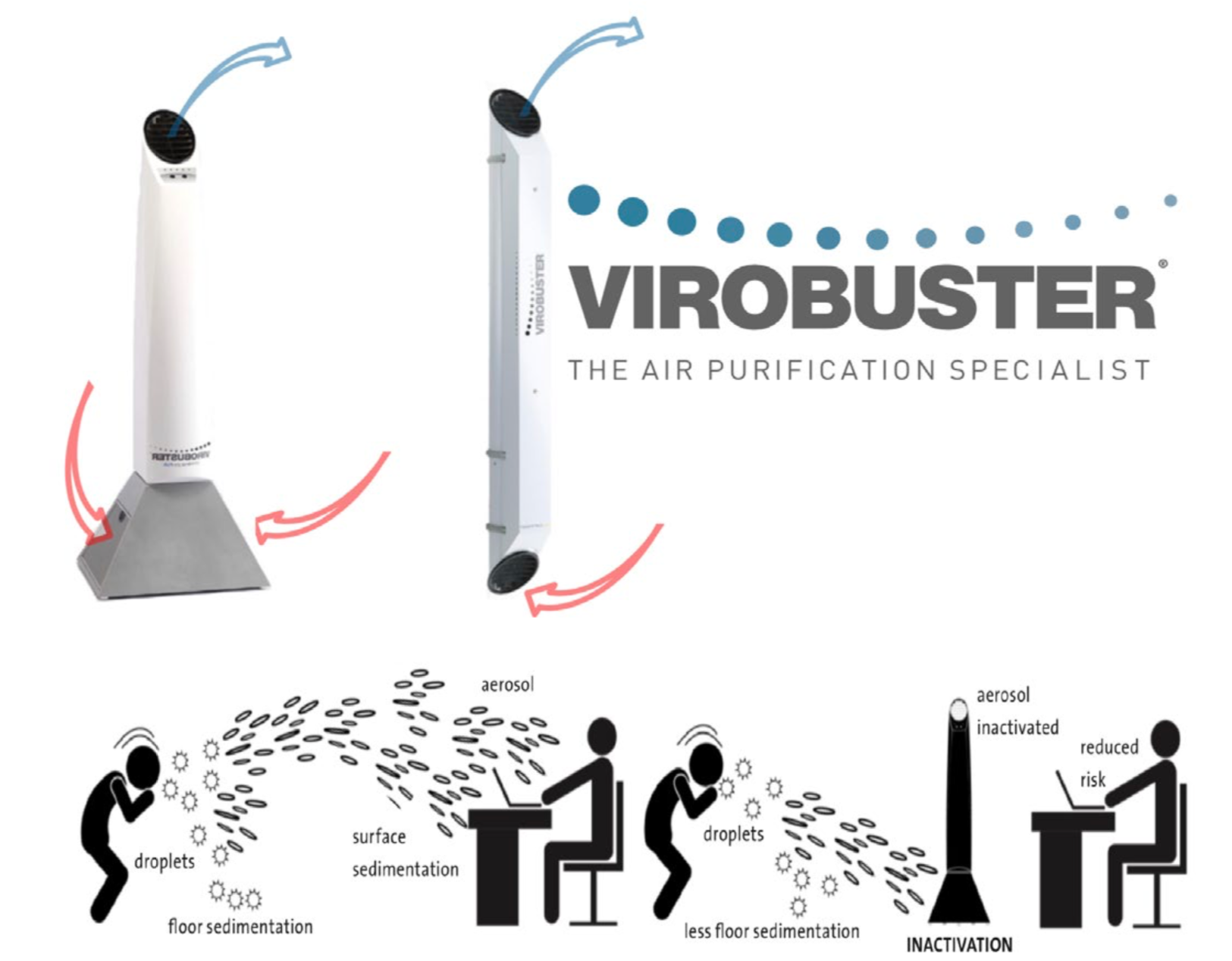

For these spaces, a powerful Stand-Alone unit can be used to guarantee the so-called "Down-Flow" movement.

The Steribase 300 plus deactivates the virus-charged air and returns it to space via a powerful “throw”.

In the bottom picture you can clearly see how the Steribase creates a safe situation by continuously extracting virus-loaded air (green) from the lady and returning clean air.

USP’s with Virobuster

STERITUBE

- Absolute sterilisation of corona virus air (> 99.99% kill)

- Retrofit in existing systems possible

- On-Demand use

- If OFF, no costs (negligible pressure drop)

- Maintenance every 3 years (10 hrs/280 days) and therefore very low life cycle costs compared to mechanical filters

- Safe and proven to use

STERIBASE

- Absolute sterilization of corona virus air (> 99.99% kill)

- Powerful enough to force the air in a room in a safe down-flow movement

- Maintenance every 3 years (10 hrs/ 280days) and therefore very low life cycle costs compared to mechanical filters

- Safe and proven use

Discussion

A constructive criticism of the current situation: How did it all get this far?

3 questions play a role in this:

- Why have viruses not played a role in air quality until now?

- Why are Down-Flow systems not standard advised?

- Why has more virus focused legislation never been drafted?

Answers:

- Because the current state of the art - mechanical filtration maybe cannot handle viruses ? And this should not be known?

- Maybe with a Down-Flow system - because of the ideal flow, less air is needed - and would therefore mean less turnover for the HVAC industry?

- Or was the Lobby of the filter & HVAC industry so strong that no legislation - aimed at viruses – was allowed as long as they did not have an "interesting" solution themselves?

The corona crisis has now revealed this quite painfully and is now turning the latent need for air hygiene into an urgent need. It definitely pays to tackle or invest in this theme because Sick building syndrome is also partly caused by poor air hygiene (PAQ) and thank goodness there are enough studies which researched the (cost) relationship between virus (eg Influenza, Noro , etc.) loaded air versus productivity and absenteeism of employees.

Cowboys

It is remarkable how many people have become UV and/or Air specialists and not only provide "the right advice" but also "the super NASA technology" that fights the virus.

Were where you in the last 20 years?

Let's make a few comments to them:

- Don't fool people with technologies that died 20 years ago (such as open UV-C robots or Upper Room disinfection)

- Please do not claim that 2D UVC can sterilize a 3D product such as a face mask or grocery

- Do not endanger people by offering technologies such as plasma or ionization.

If you still claim to be the solution, show us through:

- The efficiency of your system in a one pass through (LOG reduction)

- Efficiency in a room of 100 m2 within 10 minutes in real situation (no laboratory)

- How are both efficiencies after 1 month of work? Is the device already clogged ? Did it self-destruct? Or has the user already been killed?

- What safety certificates are there?

- And last but not least, do not sell it cheaply and ask for a ($) amount for the filter elements every 2-3 months, so that the life cycle costs rise sky high.

The fact that the authorities did not recognize the need to implement regulations does not mean that you - cowboys - can abuse the 'fear' among people.

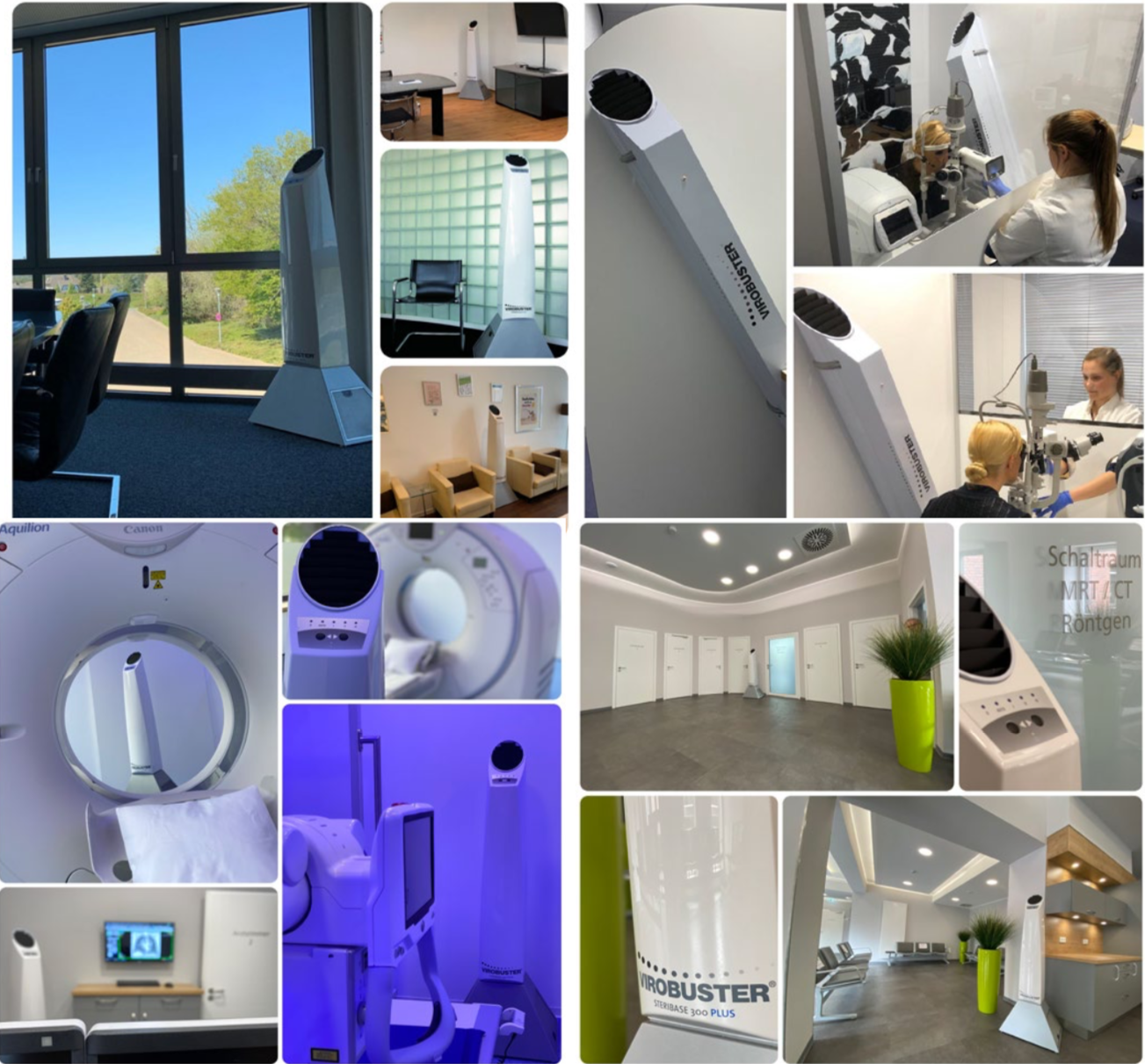

Field examples of Virobuster Steritubes in practice

A few examples from practice, which already uses the next generation “thinking”. Medical, industry and veterinary use of clean air.

A German university clinic requested a new heart-catheter operation room; the Steritubes were retrofitted in the ducting.

A Dutch clinic saw an increase of infections among newborn vulnerable children. They retrofitted the UVPE Steritubes in the ducting of the right wing and did put all vulnerable newborns over there.

An industrial potatoes plant implemented clean air protecting its cooling, transport and packaging processes. Two big HVAC installations executed with UVPE protect the whole line continuously, resulting in increased shelf life and product safety.

Even unique environments like the transport of small weeny pigs became an issue. UVPE was recognized by the RVC in London and the Danish Agriculture Ministry as leading solution against the PPRS- Virus.