Lubricants in meat preparation

Recommended lubricants in meat preparation. Products of Fuchs Lubricants.

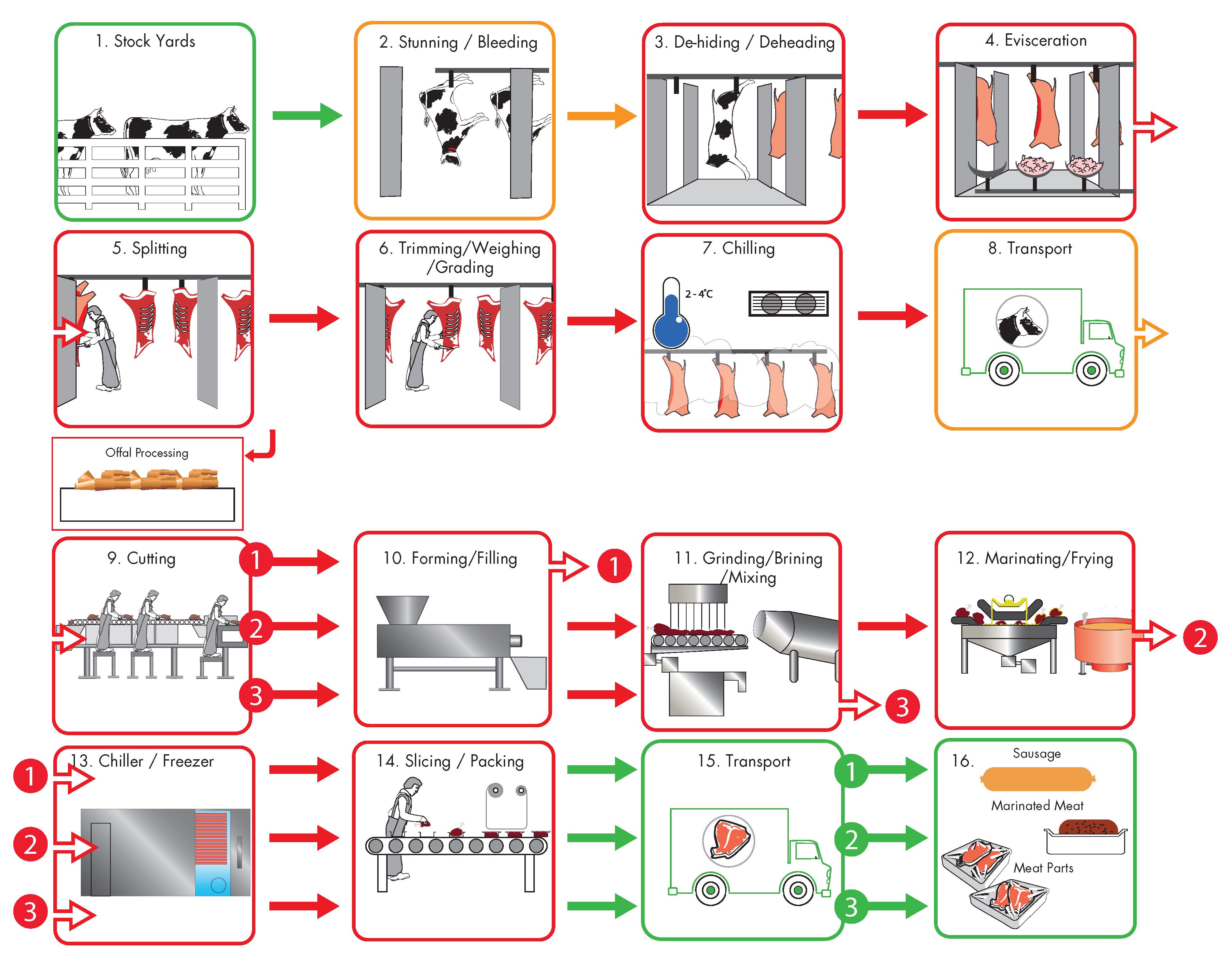

Steps in meat preparation and recommended lubricants.

1. Stack yards, stack race, slaughter floor

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| transport chain | chain oils or grease NLGI 2, water resistant | Cassida Chain Oil or Cassida EPS 2 |

| roller bearings | grease NLGI 2, water resistant | Cassida EPS 2 |

2. Hanging / stunning / bleeding

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| central conveyor system | chain oils or grease NLGI 2, water resistant | Cassida HF100, Cassida Chain Oil 150 or Cassida grease EPS 2 |

| roller bearings | grease NLGI 2, water resistant | Cassida EPS 2 |

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

3. Dehiding / deheading / neck breaker

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| roller bearings | grease NLGI 2, water resistant | Cassida EPS 2 |

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

| central conveyor system | chain oils or grease NLGI 2, water resistant | Cassida HF100, Cassida Chain Oil 150 or Cassida grease EPS 2 |

4. Evisceration

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| central conveyor system | chain oils or grease NLGI 2, water resistant | Cassida HF100, Cassida Chain Oil 150 or Cassida grease EPS 2 |

| roller bearings | grease NLGI 2, water resistant | Cassida EPS 2 |

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

5. Splitting

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

6. Trimming / Weighing / Grading

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| central conveyor system | chain oils or grease NLGI 2, water resistant | Cassida HF100, Cassida Chain Oil 150 or Cassida grease EPS 2 |

| roller bearings | grease NLGI 2, water resistant | Cassida EPS 2 |

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

7. Chilling

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| roller bearings | grease NLGI 2, water resistant | Cassida EPS 2 |

| central conveyor system | chain oils or grease NLGI 2, water resistant | Cassida HF100, Cassida Chain Oil 150 or Cassida grease EPS 2 |

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

8. Transport

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| conveyor system | chain oils or grease NLGI 2, water resistant | Cassida HF100, Cassida Chain Oil 150 or Cassida grease EPS 2 |

9 Cutting

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| roller bearings | grease NLGI 2, water resistant | Cassida EPS 2 or RLS (high rotation) |

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

10. Former / filling

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| hydraulics | hydraulic oil | Cassida HF 68 |

| roller bearings | grease NLGI 2, water resistant | Cassida EPS 2 |

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

11. Grinding / brining / mixing

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| hydraulics | hydraulic oil | Cassida HF 68 |

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

| roller bearings | grease NLGI 2, water resistant | Cassida EPS 2 |

12. Marinating / frying

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| chain conveyor | no lubrication (frying fat) or chain oil | |

| heat transfer system | heat transfer oil | FM HT 32 |

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

13. Spiral freezer / chiller

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| roller bearings | grease NLGI 2, water resistant | Cassida EPS 00 or LTS 1 |

| chain conveyor | low temperature chain oil | Cassida Chain Oil LT |

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

14. Slicing / packing

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| chain conveyor | chain oils or grease NLGI 2, water resistant | Cassida Chain Oil or Cassida EPS 2 |

| roller bearings | grease NLGI 2, water resistant | Cassida EPS 2 |

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

| vacuum pump | vacuum pump oil | Cassida VP100 |

2006/42/EC Machine directive: Supplementary essential requirements

Summary of the requirements for food machinery in the Machinery Directive.

2.1. Foodstuffs machinery and machinery for cosmetics or pharmaceutical products

2.1.1. General

Machinery intended for use with foodstuffs or with cosmetics or pharmaceutical products must be designed and constructed in such a way as to avoid any risk of infection, sickness or contagion. The following requirements must be observed:

-

materials in contact with, or intended to come into contact with, foodstuffs or cosmetics or pharmaceutical products must satisfy the conditions set down in the relevant Directives. The machinery must be designed and constructed in such a way that these materials can be cleaned before each use. Where this is not possible disposable parts must be used;

-

all surfaces in contact with foodstuffs or cosmetics or pharmaceutical products, other than surfaces of disposable parts, must:

-

be smooth and have neither ridges nor crevices which could harbour organic materials. The same applies to their joinings,

-

be designed and constructed in such a way as to reduce the projections, edges and recesses of assemblies to a minimum,

-

be easily cleaned and disinfected, where necessary after removing easily dismantled parts; the inside surfaces must have curves with a radius sufficient to allow thorough cleaning;

-

-

it must be possible for liquids, gases and aerosols deriving from foodstuffs, cosmetics or pharmaceutical products as well as from cleaning, disinfecting and rinsing fluids to be completely discharged from the machinery (if possible, in a ‘cleaning’ position);

-

machinery must be designed and constructed in such a way as to prevent any substances or living creatures, in particular insects, from entering, or any organic matter from accumulating in, areas that cannot be cleaned;

-

machinery must be designed and constructed in such a way that no ancillary substances hazardous to health, including the lubricants used, can come into contact with foodstuffs, cosmetics or pharmaceutical products. Where necessary, machinery must be designed and constructed in such a way that continuing compliance with this requirement can be checked.

2.1.2. Instructions

The instructions for foodstuffs machinery and machinery for use with cosmetics or pharmaceutical products must indicate recommended products and methods for cleaning, disinfecting and rinsing, not only for easily accessible areas but also for areas to which access is impossible or inadvisable.

Featured expert: Wouter Burggraaf