Hygienic Machine Cabling – Flexible Conduits

White paper

This white paper discusses the pro’s and con’s of the use of flexible conduits as hygienic solution for protecting and connecting cables on machinery and equipment in the food industry in compliance with legal hygiene requirements – and in line with the Practical Guideline Hygienic Cabling.

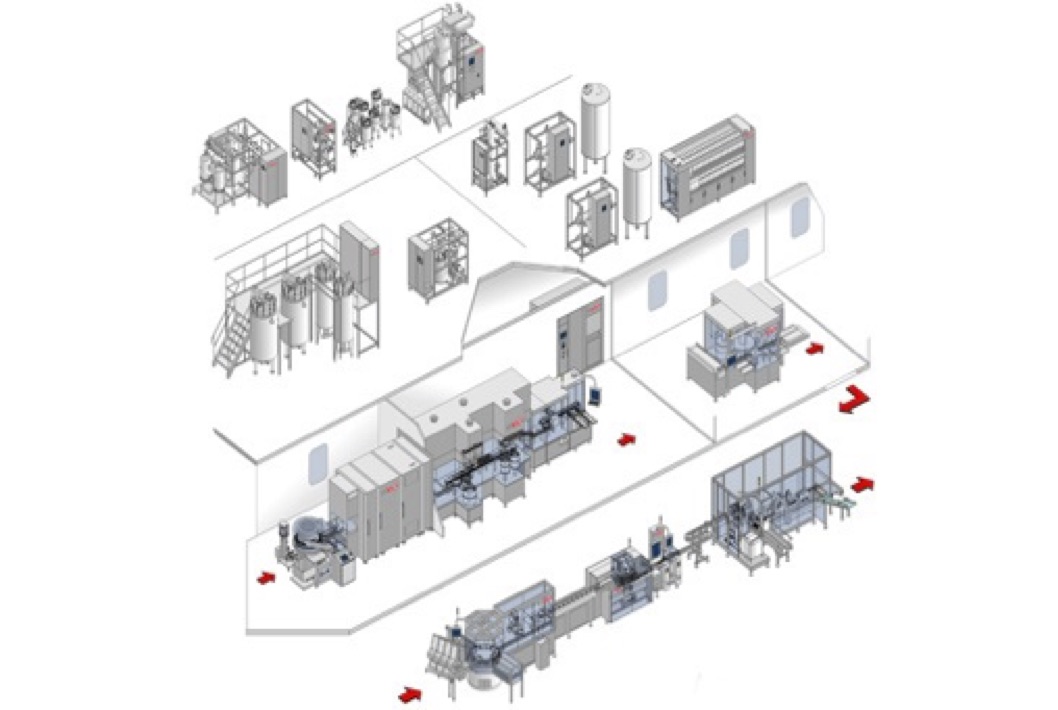

1. Need for Safe Food Production

Currently, the food industry is undergoing rapid changes, which makes hygienic design more important. Today consumers prefer products that are fresh and easy to prepare with little or no heat treatment. As a consequence, this increases the risk that micro-organisms can develop, grow, multiply and are not killed by cooking. In addition, consumers demand products with less sugar, less salt, less fat and no preservatives. This increases the risk of spoilage of the food products. Finally, because of globalisation, a mistake made by one manufacturer, however small, will affect the food industry anywhere in the world.

The biggest threat to food hygiene is undoubtedly micro-organisms. They are so tiny that they are only visible under a microscope – and by the time we can see them with the naked eye it is too late. Hygienic design in food factories is essential in all stages of the production process, from the use of materials such as stainless steel to specially designed seals. Although the importance of hygiene in food processing is obvious, there are still see many flaws in today’s food production equipment that could lead to product recall in the market.

The European Commission recognises the importance of food safety. This has resulted in the following documents, particularly relevant for food processing equipment design:

- the food hygiene regulation

- the machine directive and

- the food contact materials regulation.

The EU food hygiene directive EC852/2004 also mandates the evaluation of possible risks in every segment of the production process, using Hazard Analysis Critical Control Points (HACCP). But there are also explicit requirements regarding buildings and equipment.

When the equipment manufacturer sells, he is obliged to place the CE sign on his machine. This means that he declares that the equipment fulfils all relevant EU legislation. This includes the machine directive 2004/42/EC with the specific paragraph for machinery intended for use with foodstuffs or with cosmetics or pharmaceutical products in order to avoid any risk of food or biochemical contamination.

One important aspect of these laws is that all parts of the production line should be accessible for cleaning.

The European Standard EN-1672-2 is compliant with the machinery directive and divides food equipment in different zones or areas:

- Food area

Area composed of surfaces in contact with food; the food area also includes the surfaces with which the product may come into contact under intended conditions of use, after which it returns into the product. - Splash area

Area composed of surfaces on which part of the food may splash or flow along under intended conditions of use and does not return into the product. - Non food area

Any area other than those specified above.

The USA has similar hygiene regulations in place under the Food Safety Modernisation Act (FSMA) and use ISO 14159 and NSF/ANSI 169 as the equivalent of EN 1672-2 with similar definitions. For food-grade materials the US Code of Federal Regulations 21 CFR 170-1999 with the ANSI/NSF International Standard 51 is valid for the USA.

In 2015, in The Netherlands, a national working party, consisting of a select group of specialists from the industry, has written and published a Practical Guideline Hygienic Cabling. This working party included representatives from the food industry, consisting of food manufacturers, engineering companies, cabling companies, suppliers of different components for cabling and a cleaning company. In this working party forum all relevant regulations and standards regarding general safety, food safety and hygiene have been discussed and clearly documented and listed in a guideline which can be accessed on www.safefoodfactory.com/en/guidelines.

2. Hygienic cable solutions

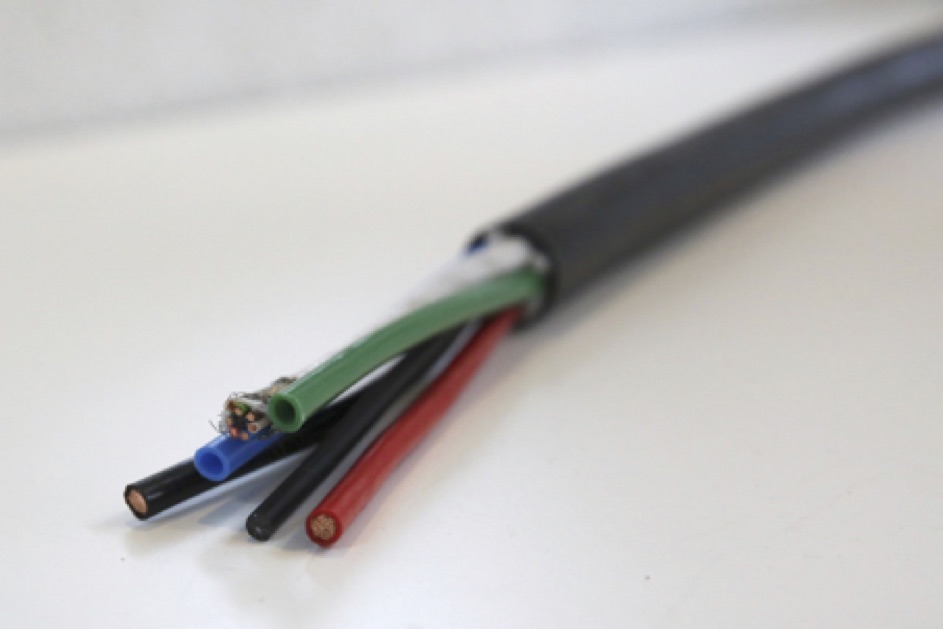

If cables cannot be avoided in certain food or splash areas, the second recommendation of the Practical Guideline Hygienic Cabling (chapter 4.2) is to limit the number of individual wires and hoses and to bundle them wherever possible.

This can be done with

- combi cables

- (flexible) conduits.

Nowadays, there is a development to combine different signal wires and power wires in standard available cables. While this in itself is a positive step and improvement on traditional methods of loose wires, many applications today require a solution which can accommodate numerous wiring options as well as compressed air tubes, signal wires and/or liquids, that cannot be supplied or are not available in the form of a single cable.

3. Development conduits

For safety reasons it is obliged in the US to install cables in a rigid conduit. To make the connection from a rigid conduit to a motor a flexible conduit is used. Over the years, flexible conduits have evolved from a simple hose to a cable protection system that is robust, reliable and durable in which several wires or cables can be installed.

3.1 Objection – The Probability of Conduit Rupturing

In the working party Hygienic Cabling some members were, from the offset, sceptical about the use of flexible conduits, because of the fear that they might rupture during use.

3.2 Different Flexible Conduit Options to Choose From

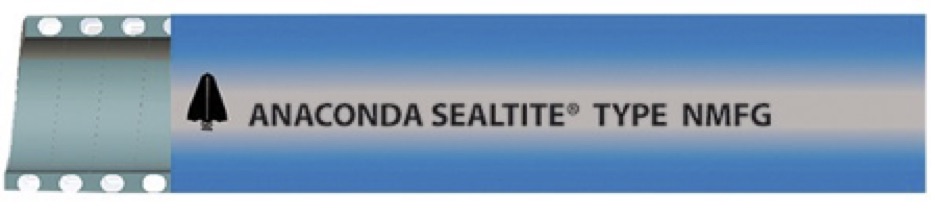

One of the companies selected to participate in the working party was Anamet Europe BV, a company that manufactures flexible conduits at its headquarters in Amsterdam, the Netherlands. One of the flexible conduits they developed specifically for protecting and bundling cables in food applications is Sealtite NMFG, a spiral reinforced PVC conduit. The spiral reinforcement improves the impact resistance of the conduit, though the compression resistance is light (class 1, very light (125 N)) according to EN-IEC 61386.

Anamet Europe BV continued to research and develop its range of flexible conduits to meet the NSF/ANSI 51 food-grade requirements and NSF/ANSI 169 certification as well as to gain approval in accordance with FDA CFR 21 regulations.

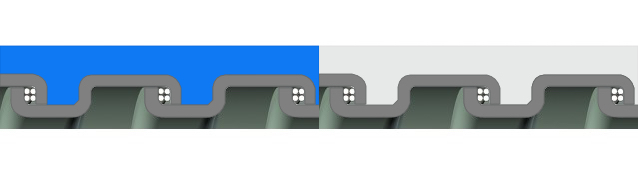

One new product to emerge from this program was Sealtite FG (Food Grade). It is available in white and light blue and complies with the hygienic requirements of the industry and is constructed as follows:

- a square-locked galvanized core with cord packing to maximize flexibility and, simultaneously, provide a construction which is strong, durable and reliable

- a thick, smooth thermoplastic jacket that is easy to clean

By using the galvanized core instead of the spiral reinforcement, the compression resistance increased from 125 (class 1) to 1,250 Newton (class 4), so the probability that the conduit will crack is virtually non existent. The impact is also improved from 2 (class 3) to 6 Joule (class 4). The tensile strength is for both cases similar (1,000 Newton, class 4).

In-situ and experimental testing of Sealtite FG conduit showed that the thermoplastic cover is:

- easy to clean dry (no adhesion of dry powders)

- easy to clean controlled wet (with a clean wet tissue)

- easy to clean wet (with flushing water)

3.3 Objection – Overcoming the issue of Cable Bundling

Another objection voiced in the beginning by some members of the working party was that it could prove difficult to bundle and thread several cables and hoses through a conduit without creating a blockage and that it would be practically impossible to add an extra cable or hose once an assembly has been mounted.

The last item is insurmountable. When an extra cable has to be added to an existing conduit installation, all the cables and hoses have to be removed. In principle, they can only be brought into the conduit as a bundle. The working party also recognised and recommended that all cables and hoses should be planned in advance, so that none have to be added afterwards - as an afterthought. Nowadays, to achieve a proper design, not only is the equipment drawn in 3-D, but also the number, size and space requirements of all cables and hoses to be accommodated in the conduit have to be known and defined during the in-design phase.

The problem determining and optimising the amount of cables and hoses that can fit in a conduit and therefore prevent blockage occurring can be solved by taking the following factors into account during the in-design phase:

- use larger sizes of conduit (and fittings) 3/8” to 2” (outside 17.8 – 59.9 mm) than the diameter of the cable/hose bundle to be installed

- use the inner diameter of the fitting as the gauge for the number of cable and hoses that can fit in the conduit: note the inner diameter of the fitting is always (10-20%) smaller than the internal diameter of the flexible conduit (inside 10.4 – 47.8 mm)

- that the square-locked galvanized core of the conduit is rounded inside and will not block the installation of the wire/hose bundle when it is being passed through.

The conclusion after testing was: if the bundle of cables/hoses can pass the fitting, it will fit without problem in the flexible conduit.

3.4 Objection – Dealing with the issue of hollow body

The last discussion item or issue addressed by the working group was the hollow body issue. Some food companies have a clear policy on this: limit the hollow body, because if damaged, vermin (insects), dirt and/or water could enter and create a ‘not cleanable’ situation.

Not all hollow bodies can be avoided though. Examples are electrical cabinets, motor- and instrumentation-connection blocks.

The criteria are that a hollow body should be:

- sealed during lifetime or

- any damage is detected immediately.

3.5 Conduit

The absence of rupturing (class 4) and the high impact class 4, ensures that flexible conduit in or around equipment is strong and robust enough – unless it is subjected to abnormal conditions like a forklift truck or another heavy object impacting it and damaging it. It is therefore recommended to perform regular inspection on the condition of the conduit to ensure it is still fit for purpose and in tact.

3.6 Fittings

Another point that has to be taken into consideration is the fittings including the use of fittings which connect the conduit to the field component at one end and an electrical cabinet on the other.

Special SS 316, IP68 (according EN 60529) and IP69K (according DIN 40050-9), high pressure Food Grade fittings have been developed which prevent the infiltration of dust, water or other contaminants. These fittings feature a smooth, contour free design, suitable for wipe or hose down, to complement the smooth, washable exterior of the Sealtite FG and NMFG Food Grade conduits referred to above.

3.7 Moisture

In spite of the water tightness of the fitting sometimes moisture is found in the electrical cabinet and conduits. This is especially valid when used in cold production environments, like meat plants. This is most likely due to maintenance taking place after cleaning. At that time there is a high humidity in the air at relatively high temperatures (70% RH at 25°C: 14 g/m3 air). It is better to wait with maintenance until the relative humidity is below the condensation level during operation (condensation takes place at 5°C when the air is saturated with 5.7 g water/m3). Most electrical cabinets are heated up during production to 25°C or more and/or are equipped with small anti-condensations non-return valves.

When preparing new conduits for cold application the RH should be 25% or less at 25°C to avoid condensation later. When the conduit is in open connection with an electrical cabinet condensate will disappear in due time.

4. Which items are left open for the flexible concept?

4.1 Multi insertions connector

Flexible conduits offer an unlimited possibility to bundle cables and hoses (even water hose to cool field components). Phoenix and Harting have developed hygienic, heavy duty connectors to combine the content of the flexible conduits to accommodate standard wire & hose compatible insertions. The present connection of the housing of the largest heavy duty connectors (45-50 mm) is too small for the large size hygienic fittings (53 – 85 mm for 1” – 2” flexible conduits).

Phoenix multi connector with standard wire & hose compatible insertions.

As an active member of the working party, Phoenix is developing a new connection at the large side of the housing of the heavy duty connector, to make a hygienic connection of the conduit possible.

4.2 Halogen-free material

In one of the meetings, one of the working party members made clear their company’s new internal policy to prohibit the use of halogen containing cables. Anamet Europe BV has developed an alternative conduit with jacket made of thermoplastic polyurethane (TPU) with the necessary flame retardant and halogen free properties. While TPU is approved for use in the food industry in accordance with EC 1935/2004 and EC 10/2011, it is not suitable for cleaning with disinfectants that contain chlorine. PVC is more suitable for use in environments where chlorine based disinfectants are used as it is the most chemical resistant polymer.

5. Conclusions

The members of the working party reconsidered the design of the flexible conduit and concluded it fully coped with all mentioned objections from the past – and that this is at the moment the best in practice alternative and solution to minimize the number of cables, and as such contributes to a higher level of hygienic design.

6. Hygienic Machine Cabling – recommendations

(from practical guideline Hygienic Cabling for the Food Industry)

- Make a full cabling plan in design phase (appendix 5)

- Consider machine zoning (chapter 3)

- Consider cleaning conditions (chapter 5)

- Consider which product could come into contact with cables

- Avoid cable binders – these are not cleanable (chapter 6.6)

- Make cables accessible – when necessary to be cleaned

- Check chemical resistance of cables

- Consider the use of the hollow frame as rigid conduit (with fitting from bottom in)

- Only use HD fitting with IP67 or better

- Consider the use of HD junction boxes to minimize the number of cables

- Consider the use of HD heavy duty connector for easy maintenance

- Build everything hygienically (chapter 4 – hazard analysis)

Examples – flexible conduits

- Motor connection – pump, blender, mixer

- Sensor cable in processes

- Connection to junction boxes

Reference Projects

- Marelec, Belgium – meat, poultry and fish process equipment

- Tomra, Netherlands and Belgium – visual inspectors

- FrieslandCampina, Netherlands – dairy industry

- Bosch, Netherlands – vertical flow packer