Food-grade lubricants: Overcoming the myths and misconceptions

of applying food-grade lubricants & greases

Research indicates that 60 per cent of U.S. food and beverage manufacturers have not yet made the switch from conventional oils and greases to food-grade lubricants, The majority of U.S. food and beverage manufacturers still rely on non-food grade mineral based oils and greases to lubricate the machinery that touches our food supply and the potential for contamination from non-food grade lubricants poses a threat to food and beverage safety. Fuchs Lubricants has taken over the commercial activities of Shell Food Grade lubricants.

Why are so many U.S. manufacturers still using non-food grade lubricants? Mythes and misconceptions about the performance of food-grade lubricants need to be dispelled and overcome - not only to assist with improving production performance, but also to help reduce contamination risks for safer food supplies. Five myths deserve closer examination.

| Myth 1: "Contamination from machinery lubricants doesn't happen" |

|---|

| Fact 1: lt happens more often than is widely known. Contamination can often be detected before the product leave.s the plant - but not all cases are |

Reported product recalls include:

- 86,000 lbs of sliced turkey that may have inadvertently been exposed to a non-food grade lubricant during processing. Consumers complained of off-colour, off-odour turkey and some consumers reported temporary intestinal discomfort. (USA)

- A packing company had to recall 490,877 lbs of smoked boneless hams after some were tainted with gear lubricant. Several customers reported a 'bad taste' and 'burning in the throat for up to three hours' after eating the ham. (USA)

- A grocery store chain issued a recall of one manufacturer's soft drinks on its shelves due to possible contamination by a lubricant that "may cause irritation if consumed." (Australia)

- A baby food producer had to recall its infant formula and milk powder after reported contamination by industrial oil and metal in their products. (Thailand)

- Another manufacturer received complaints regarding jars of baby food that "smelled of tar." Investigators found the food was contaminated with mineral oil lubricant, possibly from the manufacturing process. (UK)

Besides consumer health considerations, contaminated products can have far-reaching implications for the supplier and distributor. The cost of a recall - in storage, shipping, notifying the public and destroying bad food - is just the start. Companies may sustain damages in foregone profits, loss of reputation, consumer confidence and trust, reduced brand equity and expensive outlays to regain market share.

| Myth 2: "l am pretty sure that the lubricants I use in my plant are all food grade" |

|---|

| Fact 2: Food grade lubricants are made from components specified by the U.S. FDA for incidental contact with food. You can verify whether the lubricant is food grade or not by asking for a declaration of the formulation from the lubricant supplier, or by checking whether the product is Hl registered with a third party certifier such as NSF International |

Food-grade lubricants are readily available in the United States and a growing number of food and beverage manufacturers are using them. Any food or beverage processor not using food-grade lubricants is taking a huge risk. The U.S. Food and Drug Administration (FDA) set a 'zero tolerance' for contamination by non-food grade

lubricants and also specify the components that are allowed to make up a food grade lubricant. The US Department of Agriculture (USDA) used to approve lubricants as H1 ('for incidental food contact') and publish the list in, what was commonly known as, the 'White Book'. The USDA ceased this activity in 1998. NSF International has since taken over the 'White Book' and now registers lubricants as H1 food grade.

You can verify whether the lubricants in your plant are food grade by checking the list of NSF H1 certified non-food compounds: www.nsf.org.

| Myth 3: "Food-grade lubricant performance is inferior to traditional lubricants - they don't meet the demands of my applications" (Food plant maintenance manager) |

|---|

| Fact 3: Synthetic food grade lubricants are designed to meet a wide range of applications and generally outperform traditional food grade mineral oils |

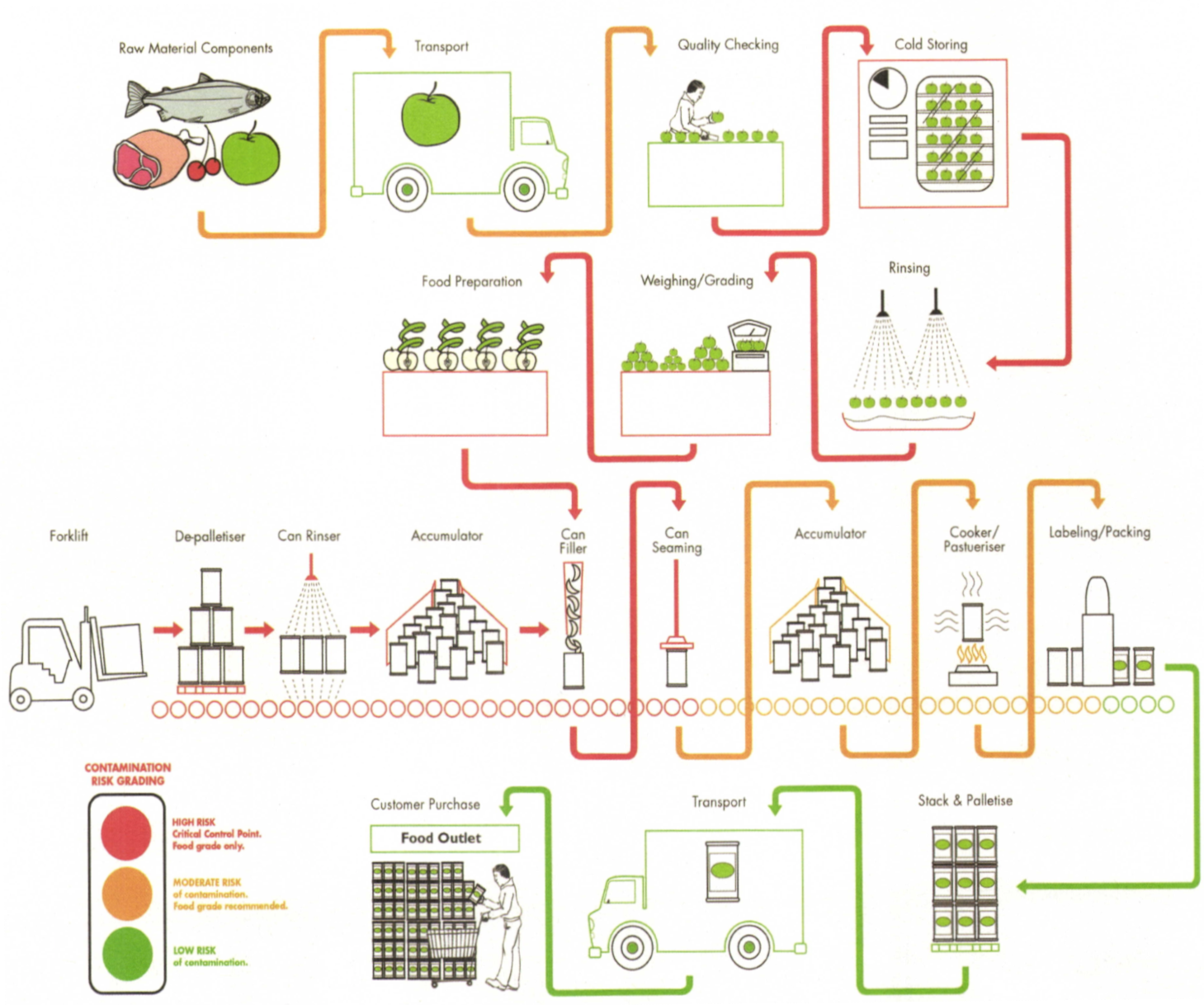

Processing machinery incorporates many moving parts requiring lubricants to maintain reliable and efficient operation. Contamination of foods and beverages can occur from drips off chains, hydraulic hose failure, oil leaks from seals and gearboxes, or a release of compressed air containing an oily mist. Using traditional non-food grade industrial oils and greases is inappropriate in this environment.

Food grade synthetic lubricants are odourless, tasteless and generally outperform traditional mineral based food grade lubricants. They are specially engineered for high performance, remaining effective in the sub-zero cold of freezers and the heat of ovens. Their increased oxidation and thermal stability, compared to a traditional mineral or white oil-based food grade lubricant, can extend equipment life and reduce downtime, lowering the cost of maintenance.

| NSF International |

|---|

| NSF's Nonfood Compounds Registration Program is based on the NSF Registration Guidelines (formerly USDA Guidelines for Obtaining Authorization of Compounds to be Used in Meat and Poultry Plants). Its evaluation process include: |

| 1 Formulation review against CFR Title 21, 9 and 40 |

| 2 Label review and confirmation of appropriate use instructions |

| 3 Verification of intended use classification and category code |

| 4 Issuance of registration letter |

| Products complying with these requirements are identified in the online NSF White Book™ Listing of proprietary substances and nonfood compounds. |

Synthetic food grade lubricants are designed for use in food and beverage manufacturing applications, improving lubrication properties and performance and offering excellent water resistance. Food grade lubricants are harmless if accidentally consumed in quantities below the maximum U.S. FDA-prescribed level of l0 ppm (10 parts per million). Synthetics do cost more than traditional mineral oils, but the initial cost of the synthetic grade mineral oil-based lubricant cannot compete. Further damages that could arise from not using H1-approved food-grade lubricants are immeasurable.

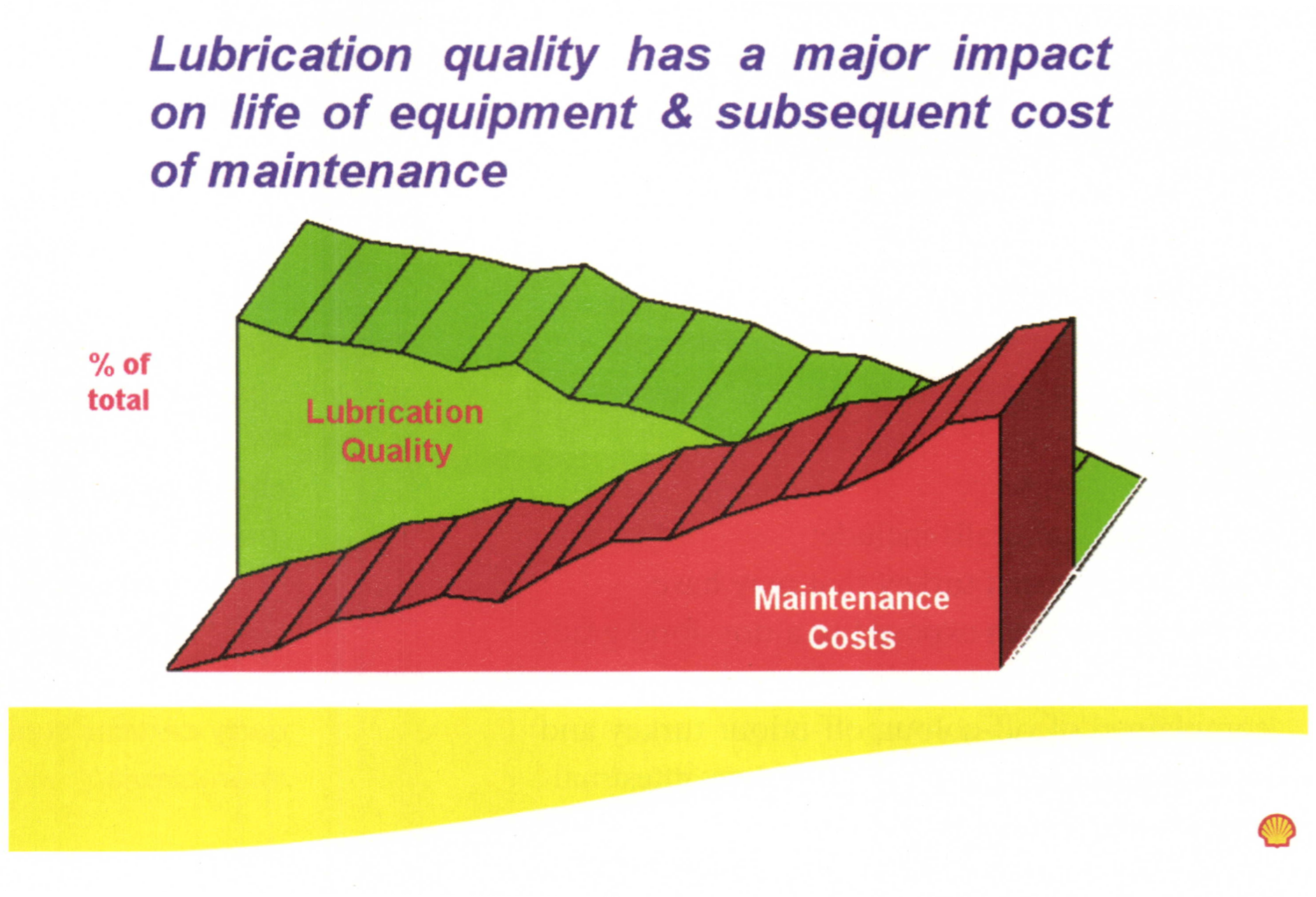

According to the Japanese Institute of Plant Maintenance (JIPM), "up to 65 per cent of mechanical equipment failures can be attributed to some form of lubrication deficiency." The JIPM developed the Total Productive Maintenance (TPM) concept to reach a perfect goal of "zero accidents, zero defects and zero failures." Lubrication failures can lead directly to production losses, so a robust lubrication program plays an effective part in plant management.

| Myth 4: "Food grade lubricanfs cost more than mineral oil products" |

|---|

| Fact 4: Synthetic food grade lubricants actually cost less long-term, because they not only reduce overall maintenance costs, but can also reduce the risk of potential liabilities from using non-food grade lubricants |

Lubrication quality can have a significant impact on equipment life. Field experience and case studies show that Shell Cassida and other food grade synthetics have a longer product life and need to be replaced less frequently in machinery. In many instances, results demonstrate up to four times more life with synthetic oils.

| Myth 5: "None of my equipment actually requires food grade lubricants for food safety" |

|---|

| Fact 5: Food grade lubricants should be used wherever there is a chance of incidental contact with food or beverage products |

For example, a can seamer using mineral food grade oil was found to cause more downtime and bearing failure than a non-food grade alternative. By switching to a food grade synthetic grease, the canning company not only saved on maintenance in the first year but also improved the quality of can seam and extended re-lubrication intervals.

Lubricants used in manufacturing facilities can make their way into the food we eat. Oil and grease droplets can seep from bearings and conveyors, can seamers, bakery ovens and other critical points of operation.

Areas of potential lubricant contamination should be identified by plant Quality Managers & Maintenance Managers. Support is available from suppliers of food grade lubricants, in the form of surveys, advice and ongoing management.

Food and beverage processing plants have a duty to take every precaution to prevent accidental lubricant contamination - contamination that could potentially harm consumers and damage a company's brand and reputation, irreparably. Synthetic food grade lubricant is a crucial step toward minimising these risks.

References

- Opportunities in Lubricants Volume III, Industrial Oils & Fluids, 2001, United States, Continuing Business Analysis, Kline& Company Inc, Copyright 2003

- JIPM Study of 696 Equipment Failures, Copyright JIPM, 1987