Lubricantes en la preparación de alimentos para animales (EN)

Lubricantes recomendados en la preparación de alimentos para animales. Productos de Fuchs Lubricants.

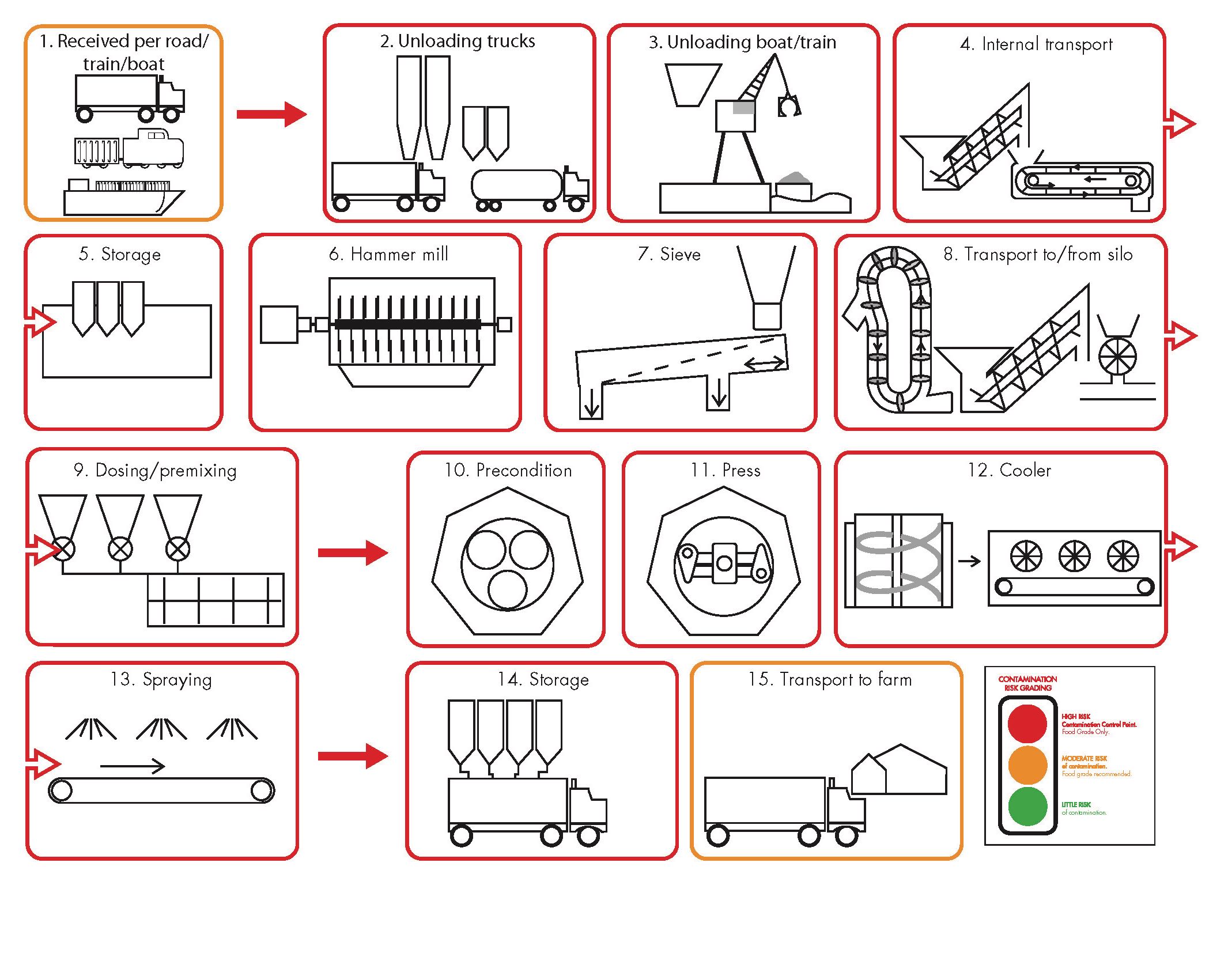

Steps in animal feed preparation and recommended lubricants.

1. Receival ingredient per boat / train / truck

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| .. Grain | - | - |

| .. Sugar byproducts | - | - |

| .. Fat/oil/fatty acids | - | - |

| .. Small functional ingredients | - | - |

2. Unloading (tanker), transport to tank

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| air compressor - blower | oil-free air | Cassida HF 100 or CR 100 |

| air compressor - piston | compressor oil | Cassida CR 100 |

| pump - gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

| stirrer - gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

3. Unloading (crane)

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| bucket | grease NLGI 2, water resistant | Cassida EPS 2 or HDS 2 |

4. Transport to silo

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| conveyor - roller bearings | filled for life | Cassida EPS 2 or HDS 2 |

5. Storage in silo

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| - | - | - |

6. Milling

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| hammermill - roller bearings | grease NLGI 2, water resistant | Cassida RLS 2 or HTS 2 (high temperature) |

7. Sieve

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

| sliding blocks | grease NLGI 2, water resistant | FM grease HD2 |

8. Transport to silo

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| screw conveyor - gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

| bucket conveyor - gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

| rotary vavle - gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

9 Dosing and pre mixing

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| rotary valve - gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

10. Preconditioner

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| hydraulic | hydraulic oil | Cassida HF 68 |

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

| roller bearings | grease NLGI 2, water resistant | Cassida EPS 2 or FM HD2 |

11. Press

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| hydraulic | hydraulic oil | Cassida HF 68 |

| roller adjustment | grease NLGI 2, water resistant | Cassida EPS 2 or HDS 2 |

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

12. Cooler

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

| roller bearings | grease NLGI 2, water resistant | Cassida EPS 2 or HDS 2 |

13. Spraying heat sensitive ingredients

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| gear box | gear oil | Cassida GL 220 or GL 460 (for worm gear) |

| roller bearings | grease NLGI 2, water resistant | Cassida EPS 2 or HDS 2 |

14. Storage in silo

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| - | - | - |

15. Transport to farm

| lubricate | application | food grade -H1 compliant option |

|---|---|---|

| air compressor - blower | oil-free air | Cassida HF 100 or CR 100 |

| air compressor - piston | compressor oil | Cassida CR 100 |

Content of Practical Guideline Hygienic compressed air in the food industry (EN)

A continuación encontrará una descripción general del contenido de la Guía práctica "Aire comprimido higiénico en la industria alimentaria" (en inglés). Para obtener acceso, debe crear una cuenta e indicar durante el registro que desea acceder a las pautas. Eso cuesta 125 euros, = por año excl. TINA. Si ya tiene una cuenta, puede enviarnos un correo electrónico y comenzaremos el procedimiento para darle acceso. La publicación en inglés seguirá pronto.

Working group members

René Bakker, Hago Food & Industrie.

Wouter Burggraaf, Burggraaf & Partners (chairman).

Maurice van Dam, Parker Hannifin (later succeeded by Michael Matthijssen).

Michael Evers, Niedax (secretary).

Jef Goossens, Boge Kompressoren B.V.

Christoph Illing, Parker Hannifin.

Edwin Lamers, Bürkert.

Koen Leeflang, Festo B.V.

Michael Matthijssen, Parker Hannifin.

Johan Nooijen, Geveke.

Norbert Rozemeijer, Ants Technology & Consulting

Roy Schep, SMC Pneumatics BV (successor of Henk Klein-Middelink and Gert-Han Konijn).

Pieter van der Schepop, Fuchs Lubricants (ad hoc member).

Herman Steen, Synamic.

Martijn Visser, previously Adsensys B.V.

Mark White, Parker Hannifin (ad hoc member).

1 Scope

The practical guideline Hygienic compressed air in the food industry deals with the hygienic aspects of

- compressed air (from outside air to consumption point)

- including all conditioning, design, verification and monitoring

- including recommendations for energy consumption reduction

for application in the food industry.

Part of the guideline is a substantiation of the hazard and risk analysis.

2 Normative references (legislation and regulations)

There are three food safety laws that need to be considered in the EU:

- Hygiene regulation Reg. 852/2004

- Machinery Directive (2006/42 / EC)

- Materials regulations Vo1935 / 2004; Vo10 / 2011

And for (breathing) air (intensive contact with (pressurised) air)

- Directive on personal protective equipment

The FDA Code of Federal Regulations applies to the United States.

The standards for compressed air, driers, filters, appendages and hoses have been taken into account when drafting the guideline.

In addition, the other practice standards have also been considered: BRC v7, IFS v6, 3-A and more.

3 Terms and definitions

Own definitions, concepts from guideline EN 1672-2 and zone classification.

4 Compressed air installation - Principles

Overview of the components that make up a compressed air system, with attention to the different principles and variants that can be chosen for a component: compressor or blower, oil-lubricated or oil-free, kind of separators, after-coolers, dryers, and filtering and separation steps.

5 Risk analysis

It discusses what can be significant hazards to the food, which can come with compressed air. This yields a number of sources that are treated individually:

- (aspirated) ambient air

- suction filter

- air compressor

After the compression:

- wet air buffer

- dryer

- filter

And finally:

- storage and distribution

The risks are discussed per source, such as

- water vapour and condensate

- particulate matter

- micro organisms

- environmental dirt

- hydrocarbons

- fragrances and flavours

- chemicals

- nutrients

- lubricating oil and grease

- dust formation by adsorbent.

Then recommendations are made for removing these hazards by source.

Where complete prevention of the hazard is not possible, the risks must be limited. It is indicated to which limits the compressed air must comply in terms of micro-organisms, moisture and the various contaminants.

6 Design requirements

In this chapter, the compressed air system is followed from intake to consumption point, and criteria and recommendations are given.

7 Verification & monitoring

Discussion of verifications of filters and of some quality characteristics of compressed air: residual moisture, residual oil, particles and microorganisms, and what measurement methods are available for this.

8 Recommendation

A brief overview where energy-saving measures are possible.

9 Working visits

The visits and discussions that the working group has held.